AUTOMATION EXPO 2022, the exhibition of automation technology for factories of the future.

Meet factory automation products and solutions of the future from Mitsubishi Electric Factory Automation at AUTOMATION EXPO 2022, for factories that want to adapt to automation that can meet their work needs. From manufacturing, maintenance, warehousing, logistics, supply chain to enterprise resource management, with activities that will bring you digital experiences for the manufacturing of the future.

GENESIS64™ Software of the Future

The newest SCADA from Mitsubishi Electric is a suite of advanced HMI, SCADA, or IoT Monitoring and Control solutions designed for Microsoft operating systems. It delivers unmatched performance with OPC, BACnet, Modbus, and open standard database connectivity.

■ Provides agility, analysis, and connectivity for a production automation perspective.

■ Supports connection via industry standard protocols.

■ Compatible with all types of devices and systems between IT and OT.

■ Real-time data visualization makes work smoother. on a variety of devices.

■ Improve performance and analytics quality with OEE, SPC, power, and error detection solutions by connecting servers to cloud computing.

CNC Direct Robot Control function.

The latest controller-equipped CNC product with Direct Robot Control compatibility, connects the robot to the controller, allowing the robot to move without a teaching box and easily manage data.

Direct Robot Control's operating system

■ Operate the robot directly by connected to the controller.

■ Order via G Code

■ Operate robots without the teaching box.

■ The robot can recognize the G Code that it activates.

■ This function is compatible with all Mitsubishi CNC M8 Series models.

■ The data recognized by the robot is stored and easily transferred to another CNC.

Industrial Computer MELIPC

High-performance industrial computers collect data from the shop floor in real time with AI technology to improve production and deliver accurate and reliable data to the IT system. Turning operations into e-F@ctory can reduce TCO while enabling lower error and more accuracy.

■ Can withstand harsh environments better than normal grade computers.

■ ‘Real-time control’ controls equipment in production areas.

■ ‘Edge Computing’ collects and processes the data sent to the IT System.

■ MELIPC can run two operating systems Windows® and VxWorks® simultaneously.

■ CC-Link IE and CC-Link IE Field Basic connections are supported.

iQ Monozukuri "tool wear diagnosis for machine"

The IoT solution for collecting data and analyzing production systems from Mitsubishi Electric improves machine performance and reduces manufacturing defects.

■ Real time graph display of working status information.

■ Quickly check the machine status and confirm the machine status on the control screen.

■ Analyze wear and predict machine life.

■ Instantly analyze machine malfunctions and prevent manufacturing defects.

■ Automatically analyze trend data values for defining characteristics.

■ Freely change tool change conditions and status confirmation values.

■ Review the alarm and diagnostic history to support timely tool changes.

Extended Warranty Contract (EWC)

Mitsubishi Electric offers EWC (Extended Warranty Contract) or yearly CNC Controller maintenance insurance with a comprehensive service to troubleshoot and repair CNC machines that cover all parts of the CNC Controller efficiently and quickly.

■ 12 months duration care.

■ Free maintenance and consulting services during business hours*

■ Supervised by Mitsubishi Electric engineers.

■ Supported models are M60/600, M70/700, M80/800.

■ Covering Bangkok and an area within a radius of 200 kilometers

e-F@ctory starter package

The starter package for the industry to adapt to the Smart Factory solves the considerations and budgets required to build an IoT system that supports visualization and initial analysis, enabling access to the IoT infrastructure in the production line by simple setting up.

■ Instantly summarize overview data such as production data, equipment operating status.

■ Check the error status and notify at once.

■ Detect problem spots and fix them in a timely manner.

■ Shows the production amount such as the total number of products, the number of products that have passed QC.

■ Monitoring the working status, managing, showing the working status of the machine.

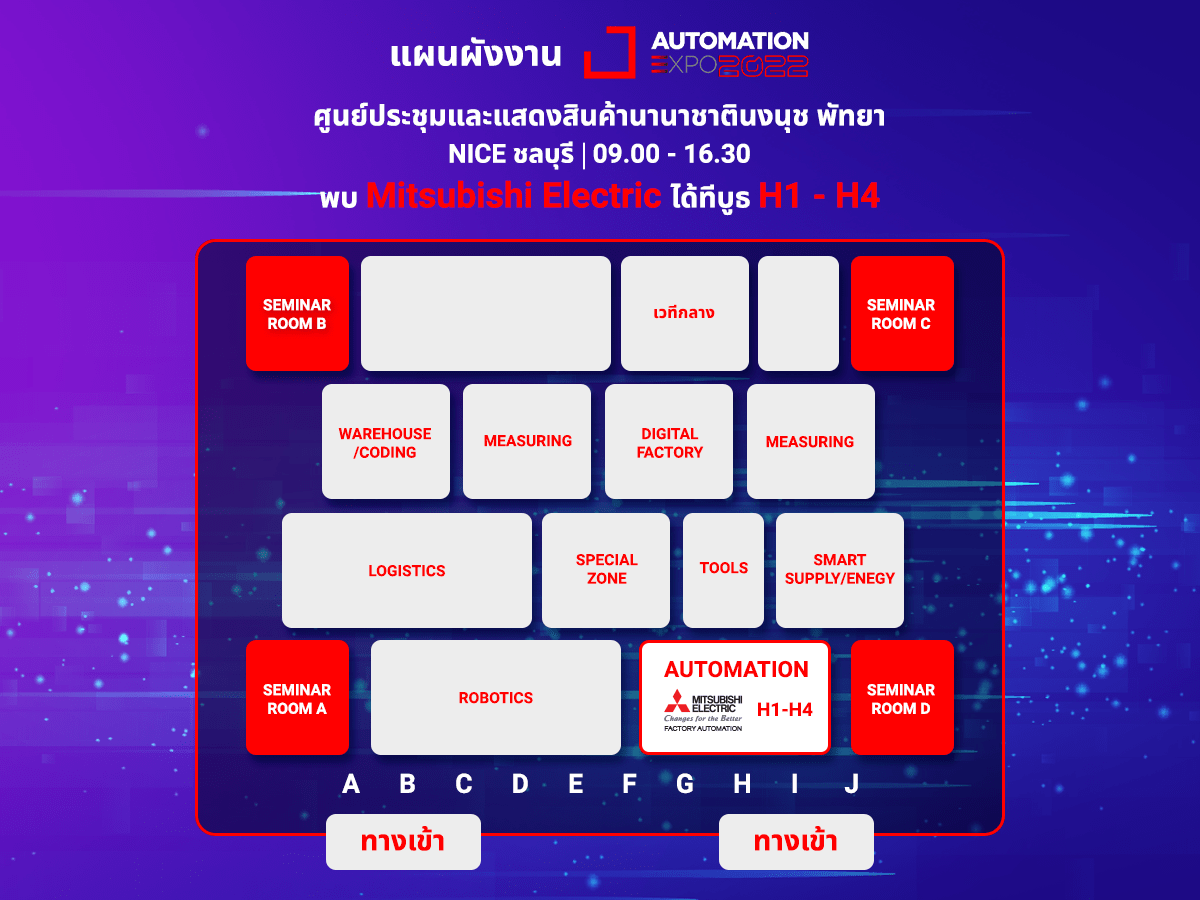

Super special, the LIKE & SHARE event, just click on the Mitsubishi Electric Factory Automation - Thailand page and share this post to your personal Facebook page and open it to Public, get a free limited edition cloth bag from Mitsubishi Electric made from good quality canvas fabric to reduce the use of plastic bags. Suitable for carrying with you for everyday use, good events like this must be received quickly! See you at booth H1 - H4 during AUTOMATION EXPO 2022.

*The event has safety measures from COVID-19.

AUTOMATION EXPO 2022 information.

■ 16 - 18 March 2022 at 9.00 - 16.30

■ Nong Nooch International Convention and Exhibition Center (NICE), Pattaya, Chonburi Booth No. H1 - H4

■ Reserve your seat at HOTLINE : 082-226-4787

■ More information, please visit website : www.automation-expo.asia