Meet the 4 highlights of Automating the World Day 2023 to create a learning society and develop automation technology skills, pushing Thailand towards Industry 4.0.

Meet the 4 highlights of Automating the World Day 2023 to create a learning society and develop automation technology skills, pushing Thailand towards Industry 4.0.

Mitsubishi Electric Factory Automation (Thailand) Co., Ltd. joins forces with partners to organize Automating the World Day 2023 on 20-21 July 2023 at EEC Automation Park, Burapha University to connect industry and education, creating a society of exchange, learning and developing automation technology skills for personnel in the Thai education sector in response to the country's development policy to keep pace with Industry 4.0.

What is there to follow at this event? Ms. Sureerat Phadungsakviriya, senior marketing engineer, supervisor in charge of technology management, showcases, and education from Marketing department, Mitsubishi Electric Factory Automation (Thailand) Co., Ltd. will provide updates and talk about the mission to develop Thai education that Mitsubishi Electric Factory Automation has carried out in conjunction with the business for a long time.

Ms. Sureerat Phadungsakviriya, senior marketing engineer, supervisor in charge of technology management, showcases, and education from Marketing department, Mitsubishi Electric Factory Automation (Thailand) Co., Ltd.

Mitsubishi Electric Factory Automation is ready to host the Mitsubishi Electric Cup Automation (MECA) competition, which will be held for the first time in Thailand at the Automating the World Day 2023 event.

“ที่ผ่านมา Mitsubishi Electric Factory Automation Mitsubishi Electric Factory Automation sees that human development must meet quality standards, so it organizes a Tournament in the form of a competition with vocational institutes across the country every year. And there is also a cooperation in organizing competitions in this format at the university level, for example, with the Rajamangala Universities of Technology network all over the country and the Technology Promotion Association (Thailand-Japan), so we have experience in organizing competitions in automation with the sector that have been studying all over the country.”

Ms. Sureerat pointed out the role in the development of the education sector in the form of an automation technology skill competition that Mitsubishi Electric Factory Automation has joined as a sponsor in educational institutes at all levels before giving information to the event of Automating the World Day 2023 that

“From the experience of organizing events with the education sector, today Mitsubishi Electric Factory Automation is ready to organize its own competition (MECA) under the concept "Automation the World". Therefore, the event of Automation the World Day 2023 took place which will be held on July 20-21, 2023, by requesting to use the EEC Automation Park area to organize this event."

“In this event, we will gather industry partners together to meet with students who we have planned to jointly develop the potential and skills of these students through training, participation in various skills competitions. We expect this effective mechanism to really help create skills for Thai students, and when the partners come to see, they will know that this group of quality and work can definitely work. Therefore, making these two parties come together can help reduce the recruitment process. It is called creating a shortcut for both the industry and the academic sector to meet in this event.”

“And we have also invited the Mitsubishi Electric Group in Thailand to join us in this work because in Thailand Mitsubishi Electric has a total of 11 affiliated companies in the vary of manufacturing industries. Other affiliated companies will have the opportunity to consider the knowledge and abilities of the students attending this event in order to be selected as employees in various positions in the future.”

“Furthermore, at this Mitsubishi Electric Cup Automation (MECA) event, we have also cooperated with organizations like Thai Automation and Robotics Association (TARA), Thai-German Institute (TGI) and Microsoft (Thailand) Co., Ltd. etc. And we also have cooperation with JFAC Industrial Electrical and Automation Training Center to come to train in the Japanese Wiring Standard. In the past, students often lacked this skill, which would mainly learn programming skills, but in fact, Wiring is also very important.

“Later, there will be training and learning about the operation of the machine. At this point, there will be a partner company from Auto Didactic Co., Ltd. that makes an educational learning package as a teacher and Mitsubishi Electric will teach about Programing Automation, including Digital Twin, which is a concept of the competition in which we use Mitsubishi's new solutions that will be promoted in Thailand as 3D SIMULATOR MELSOFT Gemini, which reinforces our work as a platform to learn these important skills to prepare for Industry 4.0 further.”

The Mitsubishi Electric Cup Automation (MECA) competitions are held around the world. Ms. Sureerat gave an example that China has held this event at various educational institutions for 15 consecutive years. Other countries that have organized this event include Vietnam, India, Brazil and Thailand will be the next country to host this event in this year for first time. Which in the future, there will be many countries that will join this event together on a global level, which is a big goal after organizing the event at the national level as well

Reveal 4 highlights that everyone will meet in Automating the World Day 2023

and the Mitsubishi Electric Cup Automation or MECA event in Thailand this year, with the main objective being cooperation and matching between industry and academia. The theme of this year's event is set to be a Digital Twin theme that aims to spread the concept of this technology more widely.”

“Because Digital Twin is an industrial factory concept that can predict the operation of the machine beforehand in order to plan the production in the industrial sector. Students who attended the event saw the real automation technology used in the industrial sector because of the Digital Twin concept, which is real-time monitoring of the factory to collect data for analysis and try to adjust the production line first before going to actually do it in the manufacturing sector which has the benefit of reducing costs and reducing production time, but in the education sector will use training sets instead.

In addition, Ms. Sureerat also concluded the 4 highlights that will be met in this event as well.

∎ Mitsubishi Electric Cup Automation (MECA) Competition

Prepare to meet the competition of youngsters at the university level starting from preparing for the competitors with training at the EEC Automation Park between 28-30 June 2023, where the training topics will range from Wiring Training by the JFAC Training Center and DOBOT Training by Auto Didactic, including training for new Mitsubishi 3D SIMULATOR MELSOFT Gemini solutions. On 20-21 July 2023, there will be a competition in various skills that have been trained, including GENISIS64 and skills in REAL TIME MONITORING too.

∎ Fablab Competition

It is a robotic arm control competition at the high school level that this year there will be 10 teams participating in the competition. In 1 team, there will be 2 students from grades 4-6 and 1 advisor for children to learn the basic mechanics of a robotic arm.

∎ Mitsubishi IIoT Solution Workshop Seminar

Seminar to provide knowledge on modern automation technology that the manufacturing industry must use to drive towards Industry 4.0.

∎ Small Booth by e-Factory Alliances

Update knowledge and modern automation technology from partners and networks of Mitsubishi Electric Factory Automation who will come to the booth and be ready to answer all questions at this event.

“Therefore, both the Fablab Competition is an opportunity for high school students to learn about automation technology from an early age, which will contribute to improving their learning skills to go faster and further. And at the event, you will also see university students competing in the MECA Competition and programming automation programs, which will further inspire them to see themselves in the future.”

“The IoT Solution workshop Seminar will be especially useful for industry professionals to stay updated on the latest automation technologies from experts, and the Small Booth by e-Factory Alliances will showcase the technology of various brands. This is an opportunity for brand owners to meet with students, students at the event. On the younger side, they learn new technologies. As a result, this is an event that everyone attending will benefit from.”

Reveal the origins and reasons for doing business in parallel with the development of Thai education of Mitsubishi Electric Factory Automation (Thailand).

When mentioning the name of Mitsubishi Electric Factory Automation, everyone will know that it is a Japanese company that has expanded its business base in Thailand and is a leading organization that offers automation solutions for the Thai manufacturing industry for a long time. But there is another mission that has been carried out in parallel, which is to develop Thai education with awareness of the problem of a shortage of skilled workers in automation technology.

“As an organization engaged in automation or automation business, in the past, Mitsubishi Electric Factory Automation found that we lacked skilled personnel in this field. The new employees who come to work still do not have enough skills to be used in real life, so the company has an idea to play a role in the development of the Thai education sector.

“Starting from 2016, Mitsubishi Electric Factory Automation has been working with the Thai education sector, such as educational institutes both at the university level and vocational education openings in engineering, Automation and Robotics, Mechatronics, including organizing various activities with educational institutions. This concept is an initiative by the management team of Mitsubishi Electric Factory Automation who see that personnel in this field are beginning to be lacking.

“Because part of it has to be accepted as a result of problems arising in the global labor market with a lower birthrate. This trend also occurs in Thailand and Thailand is entering an aging society. At the same time, there is a lower birth rate of children, there are still children born into families who are not ready and have a high tendency to receive insufficient education, causing long-term effects on future personnel in Thailand who are not meet the needs of the country's development in the future"

“In addition, when Thai children do not grow up to meet the need for manpower of the industrial sector that is continuously developing. It also found that those who graduate and enter the labor market still lack the knowledge and skills required by the industry standards, causing an impact on the establishments that accept people and waste time training these people as well.”

“For this reason, Mitsubishi Electric Factory Automation sees these problems and wants to play a role in helping Thai society in developing human potential to meet global trends that have changed. And since we are in the technology and automation industry, we are mainly focusing on the development mission in this area. The development of this person is in line with the national policy that will develop the country in response to the direction of the development of the manufacturing industry towards Industry 4.0 as well”

“Especially when digital disruption occurs, every organization in the industry has to enter the digital transformation process. Personnel need to have more "broad knowledge" skills. Therefore, "knowing deeply" in just one aspect is not enough to develop the industrial factory to keep up with the digital disruption. Therefore, educational institutions must speed up adapting as well.”

“As Mitsubishi Electric Factory Automation has knowledge of modern manufacturing industry, we would like to transfer this knowledge and expertise to the education sector for students to learn and develop in order to prepare those necessary skills before starting work, which, if possible, will help meet the Upskill and Reskill requirements that are currently becoming the personnel development trend because the skills that people have in the past have developed is not enough to meet the current demand due to the reason of digital disruption itself.”

Ms. Sureerat Phadungsakviriya, senior marketing engineer, supervisor in charge of technology management, showcases, and education from Marketing department, Mitsubishi Electric Factory Automation (Thailand) Co., Ltd.

3 success cases collaborating with educational institutions to raise the potential of Thai children.

Later, Ms. Sureerat also gave 3 examples for the model of success that resulted from working with the education sector and creating real results in the development of personnel in the field of automation technology.

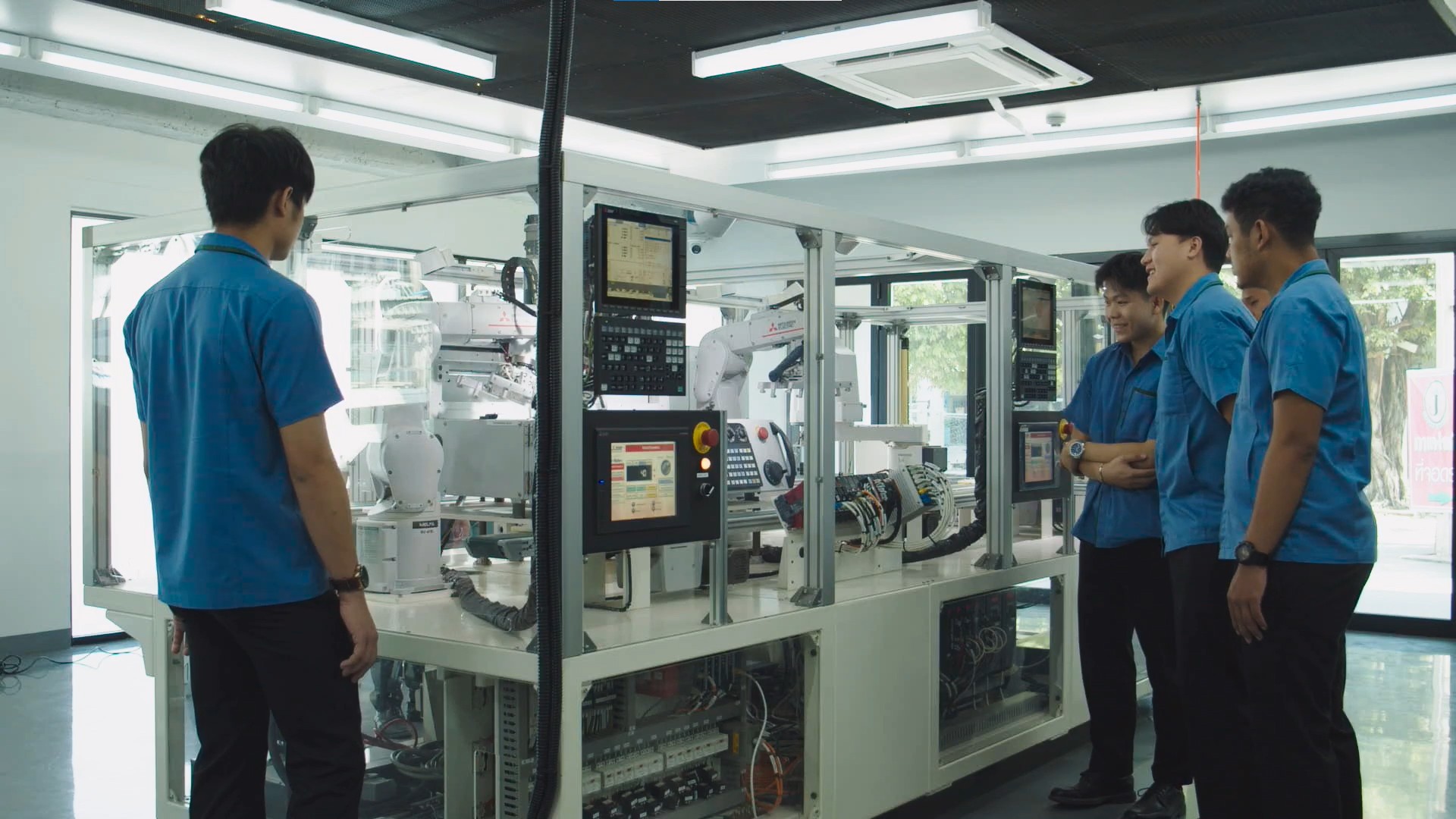

“From the experience of working with the Thai education sector in jointly transferring knowledge of automation technology in the past, we have many success cases that benefit the development of the Thai education sector. Starting from cooperation with Burapha University by jointly developing personnel with the working group to coordinate personnel development in the Eastern Special Development Zone or EEC HDC in jointly establishing the EEC Automation Park or Learning Center for industrial development and manpower in automation and robotics.”

“Mitsubishi Electric Factory Automation has joined the working group to create On the Job Training or Technical Learning courses with Burapha University including also having a part to set up various project based learning systems as well.

“In cooperation with the EEC Automation Park, we want to create Networks as Education Training Networks that are ready to extend cooperation beyond the Eastern Special Development Zone or EEC to cover all over the country, whether in the Western, the Northeast, the North, or the South, which is consistent with the National Strategy

“Because we foresee that each region will have different industries, educational institutions in each region will also play a part in helping to develop the industry in the area as well. For this reason, Mitsubishi Electric Factory Automation's approach therefore does not focus on any particular region or area, but we decided to start in the EEC area first with the country's economic development strategy that now focuses on EEC development and also have the EEC Automation Park that is a partner for joint development.

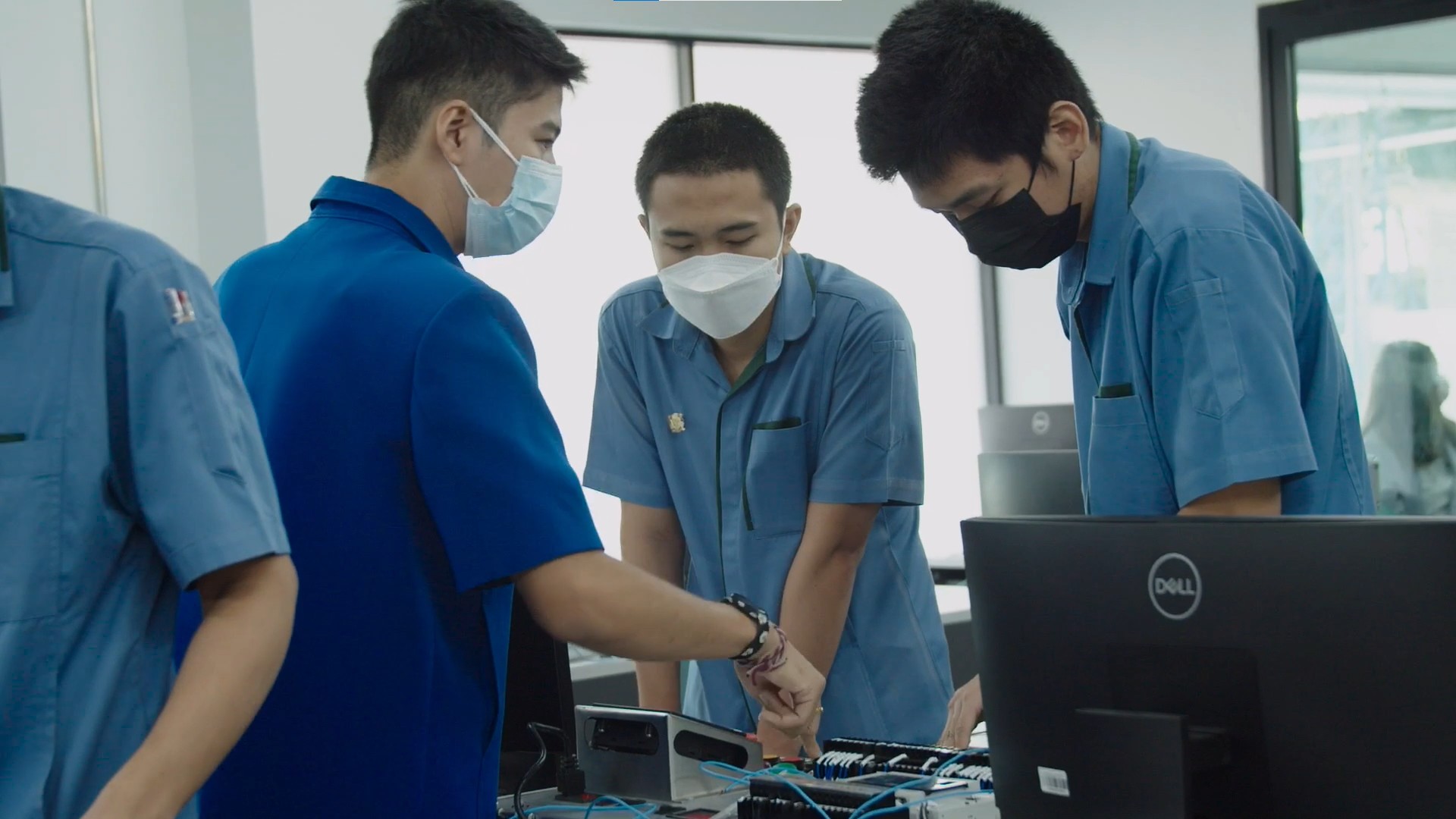

“Later, Mitsubishi Electric Factory Automation has helped develop both the curriculum and support equipment and technology for students to learn at King Mongkut's Institute of Technology Ladkrabang or KMITL. There are also applications for internships as a Long term project by accepting students in the 3rd year to work with us. After that, we consulted with the professors that if any students we saw were capable, they would bring them in to do Project Based Learning together in order to create a demonstration set as a showcase. Apply it to real work and complete the project in the 4th year.”

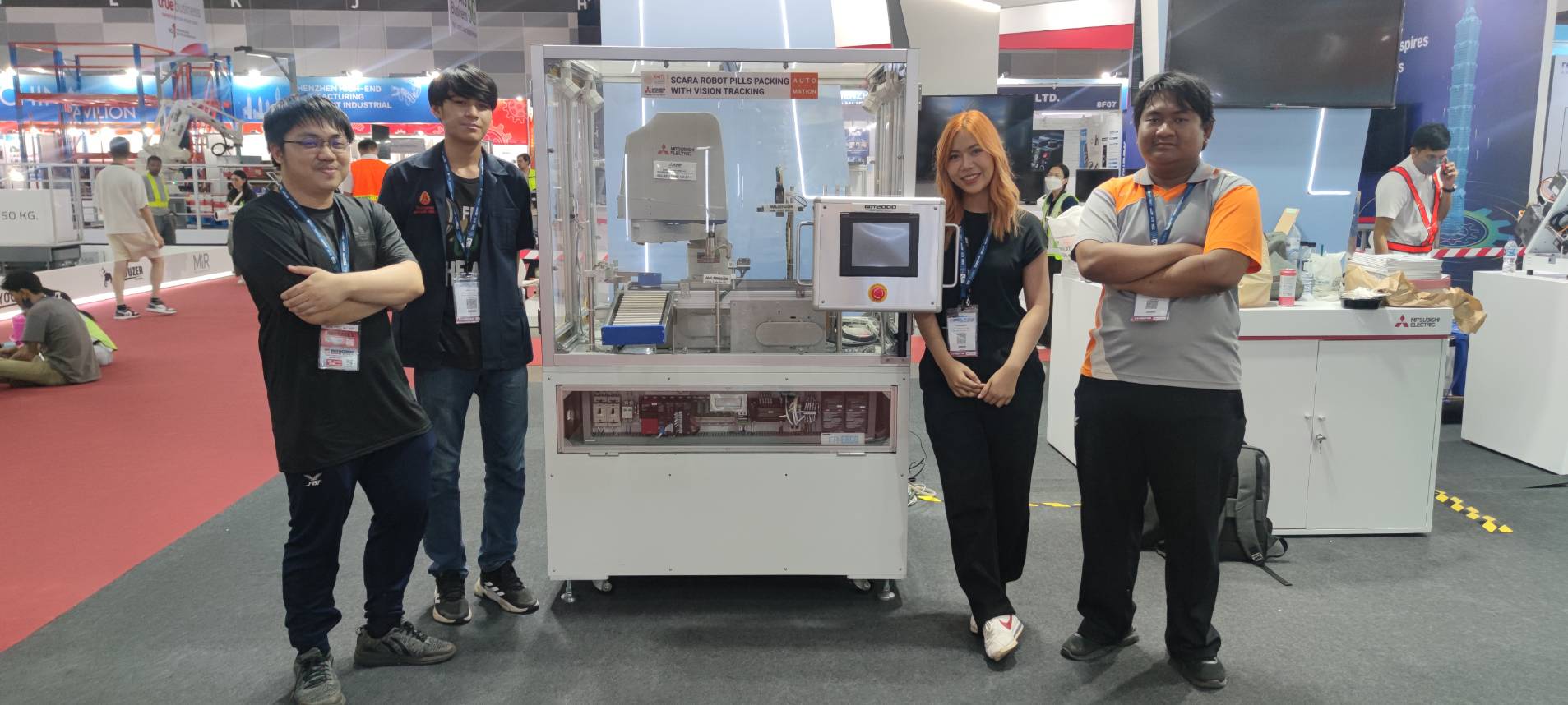

“The solution used in Project Based Learning will be the technology of Mitsubishi Electric Factory Automation, which is SCARA Robot Pills Packing together with Tracking vision, which can be ordered through a Web Application. This has been shown at the national event which is the Manufacturing Expo held at BITEC on June 21-24.

“Therefore, the result of the joint project with educational institutions is to develop personnel to equip them with skills, knowledge, and abilities that can be applied in modern industrial sectors. While you join our project, there will be a team of engineers from Mitsubishi Electric Factory Automation to teach you technical skills. In addition to knowing new technologies, the youngsters have also cultivated soft skills, such as time management because they have to come up with a project that will be showcased at the event, requiring them to plan to create that event on time. ”

“And the last success case that I would like to share is the cooperation with vocational institutes such as the Eastern College of Technology or E-Tech in Chonburi Province, where we have created a Training Network that brings basic PLC courses to students here. Including co-creating a Building Automation Showcase, a school building that allows students to design a software system that uses SCADA Genesis 64 to manage this school building by themselves, such as a monitoring system for turning on and off lights and the system, energy consumption in buildings, etc.

“In the past, we have received feedback that the teachers and the project owners will be proud and feel the ownership of this project and learn about system maintenance as well. There will be a team of engineers from Mitsubishi Electric Factory Automation as mentors to give advice and be a consultant when the system has problems.” Ms. Sureerat concluded.