Motion Controllers

MELSEC IQ-F SERIES

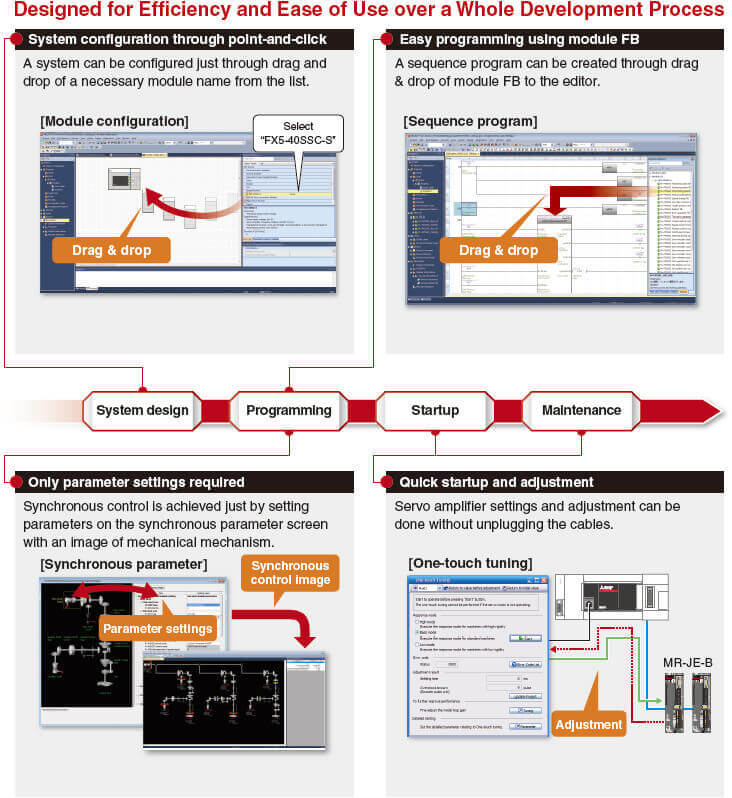

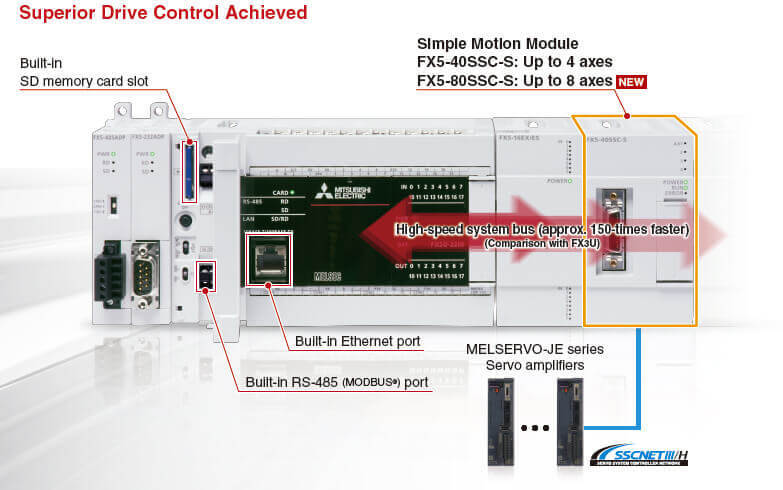

The MELSEC iQ-F series Simple Motion module achieves various controls including synchronous and cam controls with an excellent ease of use similar to Positioning modules.

Features

Synchronous/Cam Controls Contribute to Higher Performance of Small-sized EquipmentThe Simple Motion module is provided with synchronous and cam controls required for food processing machines and packaging machines. Combined with the Mitsubishi Electric's high-performance servo amplifier, the Simple Motion module enables downsizing of machinery while achieving outstanding performance. In addition, our extensive engineering environment allows you to create desired systems with ease. | Central Control via SSCNETIII/H Boosts Efficiency in StartupThe Simple Motion module can consolidate multiple servo amplifier parameters, shortening the startup time further. Also, operation information, such as power consumption and total power consumption of the servo amplifiers, can be monitored in real time, which enables further reduction in maintenance time. |

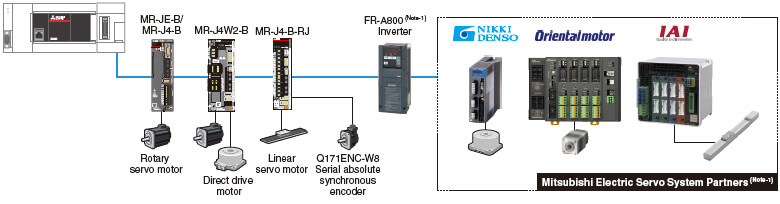

Connection with various drive products Upgraded

Not only rotary servo motors but also linear servo motors, direct drive motors, FR-A800 series inverters, and products of Mitsubishi Electric servo system partners are connectable.

(Note-1): When using a partner product or the inverter FR-A800, use one whose version supports the Simple Motion module.

The Simple Motion Module Opens up Many Possibilities for Higher Performance

High-speed Synchronous Network SSCNETIII/H

|

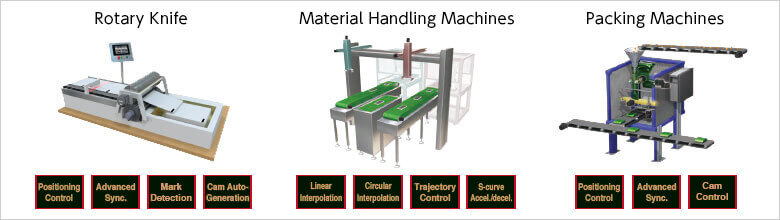

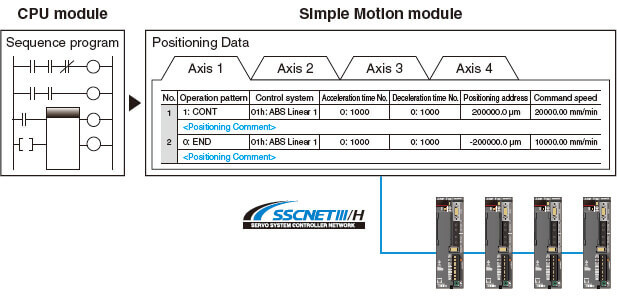

Positioning Control

Positioning control is easily performed with a sequence program starting positioning data of a point table. To respond to extensive applications, various positioning controls are available: Linear interpolation, 2-axis circular interpolation, fixed-pitch feed, and continuous trajectory controls, etc.

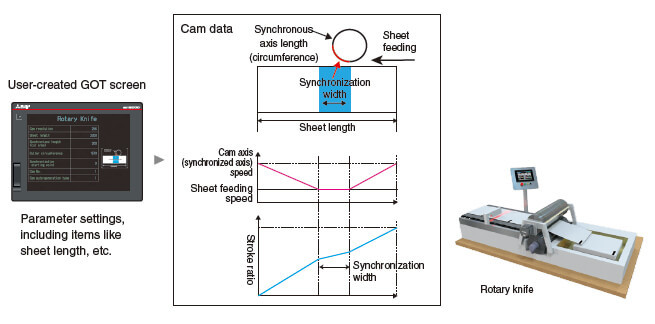

Synchronous/Cam controls

Advanced synchronous control

The advanced synchronous control is the software-based control that can be used as an alternative to mechanical control such as gear, shaft, clutch, speed change gear, and cam.

The settings are easily made with parameters on MELSOFT GX Works3. In addition, the output axes for the synchronous control are operated with a cam.

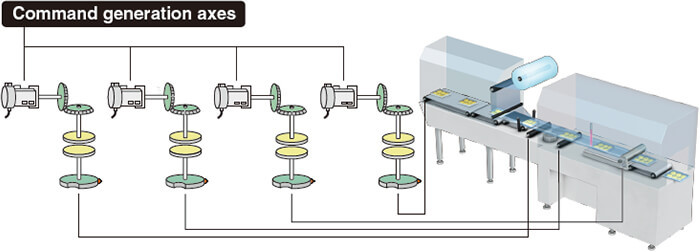

[Command generation axis] Command generation axis is the axis that performs only the command generation. It is controlled independently of other axes connected to servo amplifiers. (not counted as a control axis) Cam auto-generation

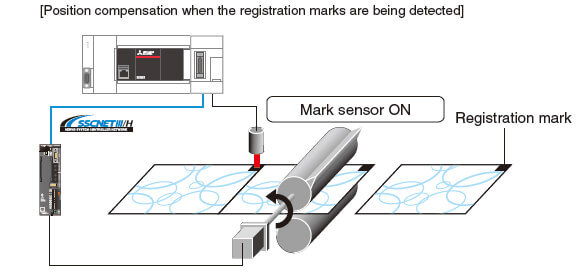

Mark Detection Function

Engineering Environment

|

Simple Motion module

The MELSEC iQ-F series Simple Motion module achieves various controls including synchronous and cam controls with an excellent ease of use similar to Positioning modules.

Functions List

|

|

Simple Motion Module |

|

|

FX5-80SSC-S |

FX5-40SSC-S |

|

|

Number of control

axes |

Up to 8 axes |

Up to 4 axes |

|

Servo amplifier

connection method |

SSCNETIII/H

(150Mbps) |

|

|

Maximum distance

between stations [m(ft.)] |

100 (328.08) |

|

|

Connectable servo

amplifier |

MR-JE-B/MR-J4(W)-BMore details |

|

|

Operation cycle[ms] |

0.888, 1.777ms |

|

|

Engineering

Environment |

MELSOFT GX Works3

(Simple Motion module setting function) |

|

|

Control modes |

Positioning control,

Position control, Speed control, Torque control, Speed-torque control, Cam

control, Advanced synchronous control, Linear interpolation (up to 4 axes),

Circular interpolation (2 axes), Trajectory control, Speed-position switching

control (ABS/INC), Position-speed switching control (INC) |

|

|

Control unit |

mm, inch, degree,

pulse |

|

|

Number of

positioning data |

600 data

(positioning data No. 1 to 600)/axis |

|

|

Acceleration/deceleration

process |

Trapezoidal

acceleration/deceleration, |

|

|

Manual control |

JOG operation,

Manual pulse generator operation, Inching operation |

|

|

Functions that

change control details |

Current value

change, Target position change function, Torque change function, Speed change

function, |

|

|

Home position return

method |

Proximity dog

method, Count method 1, Count method 2, Data set method, |

|

|

Auxiliary functions |

Forced stop

function, Hardware stroke limit function, Software stroke limit

function, |

|

|

Number of I/O

occupying points |

8 points |

|

|

24VDC internal

current consumption [A] |

0.25 |

|

|

Mass [kg] |

0.30 |

|

(Note-1): The home position return method set

in a driver (a servo amplifier) is used.