Motion Controllers

MELSEC iQ-R series

Total system performance, not individual component specifications leads to maximum performance - Based on this view, the MELSEC iQ-R series servo system controllers offer you an ideal solution to maximize your system productivity.

The MELSEC iQ-R series is provided with sophisticated dual engines: the PLC CPU engine for machine control and the Motion CPU engine for Motion control. The engines respectively process different types of control based on the characteristic of each engine while working together on data through a high-speed system bus. CPU loads are significantly distributed by these dual engines compared with a single engine, enabling any equipment to maximize its performance, even for a load change machine or multi-axis equipment |

The MELSERVO-J4 series servo amplifier is an environmentally and user friendly product, while offering industry-leading level of performance. Connecting the amplifiers to "SSCNETIII/H" optical network enables high-speed and high-accuracy control with the MR-J4 dedicated engine and high-resolution encoder. |

Select the most suitable combination of CPU engines that can reduce cost and maximize machine performance to the fullest from our extensive product line. Efficiency in designing and debugging is also improved.

Programming efficiency matters when it comes to productivity. The MELSEC iQ-R series optimizes all procedures, from designing, debugging, to startup. |

Equipped with advanced dual engines that are only possible with our cutting-edge iQ platform technology, the MELSEC iQ-R series takes a step further to accelerate the equipment revolution by collaborating with our partner companies. Now, a wide variety of SSCNETIII/H compatible partner products are available, such as stepping motors and direct drive motors. |

Features

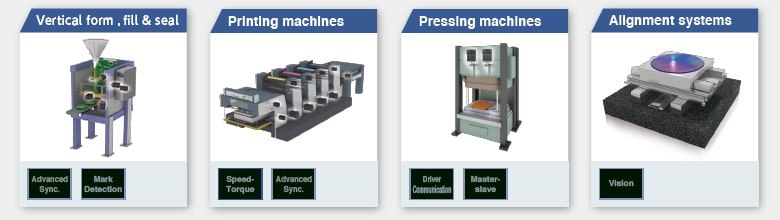

The MELSEC iQ-R series Motion controller is capable of various controls such as positioning control, speed control, torque control, tightening & press-fit control, advanced synchronous control and cam control, etc. They are applied to various machines such as X-Y tables, unwinding machines, packing machines and filling machines.

A combination of Mitsubishi's advanced PLC system, servo amplifiers, servo motors, and servo networks offers exceptional solutions that allow you to maximize your system's productivity.

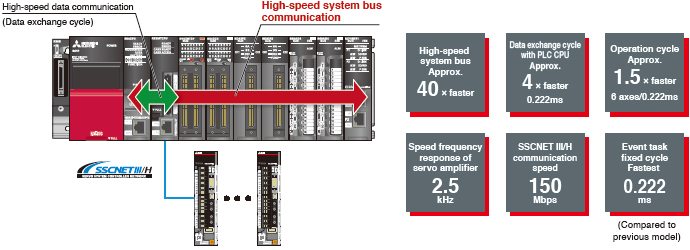

Higher Basic Performance and Further Improved Total System Performance

Experience Powerful Performance of Multiple CPU with Ease of Use Just Like Using One CPU

You can select either the Motion CPU or the PLC CPU based on the application, allowing you to configure a system more flexibly.

The easy-to-understand flowchart form is adopted by Motion SFC for Motion control programming.

Also, the direct positioning start instruction allows you to program Motion control, such as positioning and synchronous controls, just with sequence programs.

Motion CPU Memory Expansion

- The cam working area has been expanded to 16M bytes, enabling you to use more cam data with higher resolution.

- The device memory has been increased to 128k words, so even multi-axis equipment requiring more devices can be applied

- The cam data storage area has been expanded to 12M bytes. SD card is also available for storing cam data.

Ease of Use Achieved by a State-of-art CPU Buffer MemoryRevolutionary

The high-speed, high-capacity CPU buffer memory revolutionizes the data exchange between CPUs.

The PLC CPU and the Motion CPU each have a CPU buffer memory. And those buffer memories are efficiently utilized for two different purposes.

- The 2M words CPU buffer memory (Motion CPU side) is provided as standard, which is utilized for bulky data transmission and fast data updating.

- The CPU buffer memory (fixed-cycle communication area) allows 24 k words (4 CPUs in total) transmission between the PLC CPU and the Motion CPU every 0.222 ms. It is perfectly suited for receiving/transmitting highly synchronized data between multiple CPUs.

CPU Buffer MemoryProductivityEngineering

The Motion CPU and the PLC CPU are equipped with 2 M words and 512 k words CPU buffer memories respectively.

They allow for bulky data transmission and fast data update.

Example of using PLC CPU buffer memory

Bulky data such as cam data can be transferred by just a one-time transmission through the 512 k word buffer memory.

Example of using Motion CPU buffer memory

The data that is set on Motion CPU side can be reflected to the interlock in the sequence program without any delay.

CPU Buffer Memory (Fixed-cycle Communication Area)

Data can be transmitted every 0.222 ms between the PLC CPU and the Motion CPU. The CPU buffer memories (fixed-cycle communication area) are synchronized to the Motion control, optimizing the operation.

Motion SFC Program

The Motion control

program is described in flowchart form using the Motion SFC (Sequential

Function Chart) format.

The Motion SFC format program is suitable for event processing and allows the

Motion CPU to perform batch control of multiple sequential machine operations,

pursuing high event responsiveness.

Flowchart description is easy to

read and understand

·

The machine operation

procedure is visualized in the program by using the flowchart descriptions.

· A process control program can be created easily, and control details can be visualized.

Controlling sequential machine operation using

the Motion CPU

·

Servo control, I/O

control, and operation commands can be combined in the Motion SFC program.

· Motion SFC program can execute servo control by itself, eliminating the need of creating the sequence program for servo control.

High-speed Synchronous Network SSCNETIII/H

§ Communications speed is increased to 150 Mbps full duplex (equivalent to 300 Mbps half duplex), three times faster than the conventional speed.

System response is dramatically improved.

§ Smooth control of a machine is possible using

high-speed serial communications with a cycle time of 0.222 ms.

§ Synchronous communications are achieved with

SSCNETIII/H, offering technical advantages for machines that require

deterministic control.

§ Long distance wiring is possible up to 3200 m

(10498.69 ft.) per system (maximum of 100 m (328.08 ft.) between stations x

control axes up to 32 axes), suitable for large-scale systems.

§ SSCNETIII/H compatible and SSCNETIII compatible

servo amplifiers can be used together.

(The communications speed when SSCNETIII compatible products are used together

in the same system: 150 Mbps full duplex)

(Note): SSCNET (Servo System Controller Network)

Positioning Control

A variety of positioning controls, such as PTP control, position follow-up, and continuous trajectory control are available with the Motion controller.

Basic Positioning Control

· To respond to various

applications, the Motion controller offers various control methods such as PTP

control, speed control, speed-position switching control, continuous trajectory

control, position follow-up control, Speed control with fixed position stop,

and high-speed oscillation control, etc.

·

Powerful auxiliary

functions are available such as M-codes, the target position change function,

the acceleration/deceleration time change function, and the advanced S-curve

acceleration/deceleration.

· Positioning operation can be activated by Motion SFC, or the direct positioning start instruction by the PLC CPU, etc.

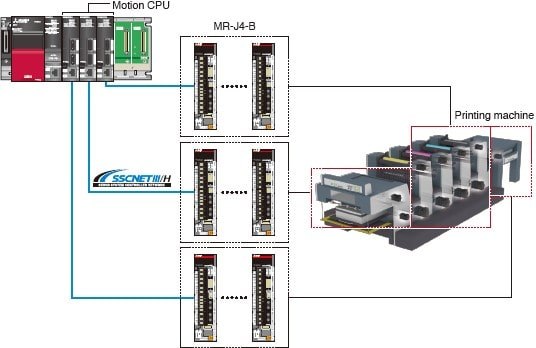

Advanced Synchronous Control

The advanced

synchronous control can be achieved using software instead of controlling

mechanically with physical gears, shafts, clutches, speed change gears or cams

etc. Additionally, a cam is easily created with the cam auto-generation

function.The synchronous control can be started/ended on axis-by-axis

basis.Axes in synchronous and positioning controls can be used together in one

program.

Speed-torque control can be performed simultaneously with the synchronous

control.

All axes are synchronized using a synchronous

encoder axis or a servo input axis.

Application Packing machines, printing

machines, diaper

manufacturing machines, tire molder, etc.

Only two axes are in synchronization. Axis 2

is set as to synchronize to axis 1. The other axes are in positioning control.

Application Tandem configuration, etc.

Multiple CPU advanced synchronous control

A large system can be configured thanks to the advanced synchronous control that allows up to 192-axis synchronization with high accuracy by use of three Motion CPU modules.

Synchronous Control Parameters

· The synchronous

control is easily executed just by setting parameters.

· One of the following

three can be set as the input axis: Synchronous encoder axis, Command

generation axis, or Servo input axis.

· "Command

generation axis" is not counted as a control axis; therefore all the

control axes can be used as output axes.

· The cam axis can be operated in linear operation (a rotary table, a ball screw, etc.), two-way operation, or feed operation by setting cam No. and cam data.

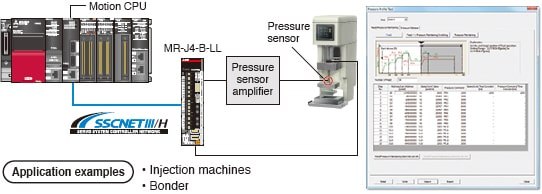

Pressure Control

The machine is controlled so that the pressure commands match the pressure sensor values; therefore pressure is maintained constant even with a changing load. Each pressure process ("Feed", "Pressure maintaining", and "Pressure release") can be set with the Pressure Profile, and those processes can be tested on MELSOFT MT Works2, which makes a changeover and adjustment easy.

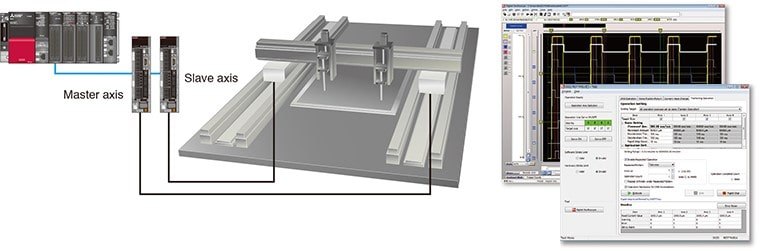

Multi-axis Adjustment Function

The multi-axis adjustment function enables

simpler servo adjustment and quicker startup for machines executing multi-axis

simultaneous operation, such as a tandem configuration.

·

Multi-axis

simultaneous JOG operation by specifying speed and acceleration/deceleration

time

·

Multi-axis

simultaneous positioning

· Multi-axis simultaneous tuning by the same settings

Machine Control Function

This Motion controller

controls the simple industrial robot by installing the machine library.

The control method of the robots is a machine control which controls in a three

dimensional (XYZ) Cartesian coordinates space.

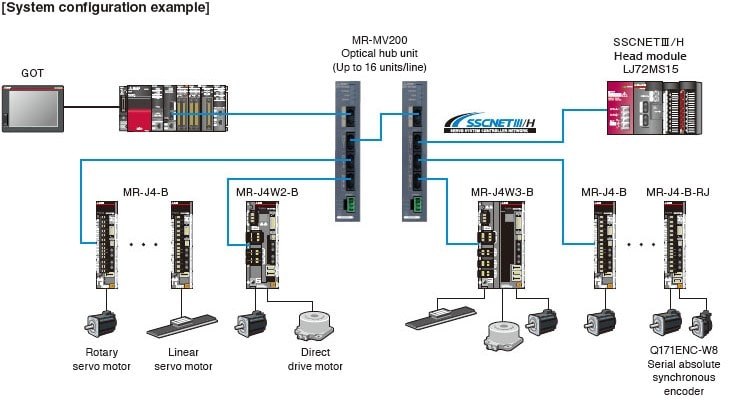

Optical Hub Unit

The MR-MV200 optical hub unit can branch a

single SSCNETIII/H network line in three separate directions. This enables

distribution of the SSCNETIII/H compatible devices with flexible wiring

arrangement. In addition, the distributed amplifier can be partly OFF for

maintenance without stopping the whole system; thus, the machine availability

can be improved.

·

The SSCNET

connect/disconnect function of the controller allows you to power off only the

desired servo amplifiers.

·

The optical hub unit

is introduced just by making some changes in wiring without making any new

settings.

·

Longer-distance wiring

becomes available by using the optical hub unit.

(Note): Be sure to confirm that "SSCNETIII/H"

is selected in the system setting when introducing the optical hub unit.

Motion Controller

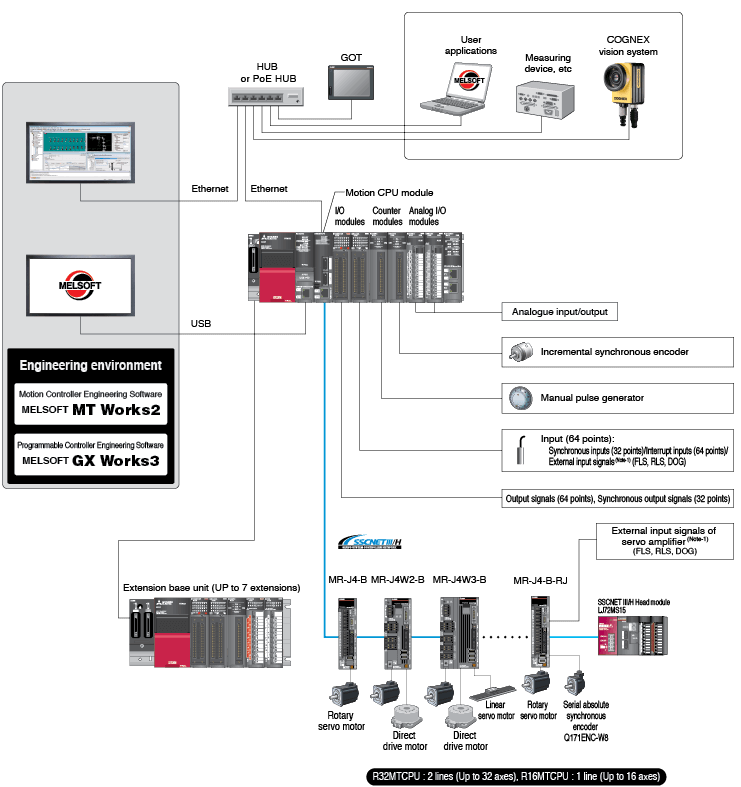

The MELSEC iQ-R series Motion controller aims to make any equipment faster and more accurate, allowing you to configure a one-of-a-kind, specialized machine system.

Simple Motion module

The MELSEC iQ-R series Simple Motion module allows you to upgrade your machine with less effort.

The R16MTCPU, R32MTCPU and R64MTCPU Motion CPUs for the iQ-R Platform provide industry-leading performance for the most demanding motion applications for the Food and Beverage, Packaging, Automotive, and Printing industries. These motion CPUs use standard I/O modules for incremental encoders and high speed inputs, so no special hardware options are required. Serial absolute synchronous encoders are connected through the MR-J4-B-RJ servo drive.

System Configuration

Motion CPU R64MTCPU/R32MTCPU/R16MTCPU Module Specifications

Notes:

1. Servo amplifiers

for SSCNET cannot be used.

2. SSCNETIII and

SSCNETIII/H cannot be combined within the same line. For R64MTCPU/R32MTCPU,

SSCNETIII and SSCNETIII/H can be set for each line.

3. For half-duplex transmission, response time may be longer depending on the external device. When connecting with an external device via a switching HUB, set to full-duplex transmission.

Motion CPU R64MTCPU/R32MTCPU/R16MTCPU Module Specifications (continued)

|

Model Number |

R64MTCPU |

R32MTCPU |

R16MTCPU |

||

|

Stocked Item |

S |

S |

S |

||

|

Number of Control Axes |

Up to 64 axes |

Up to 32 axes |

Up to 16 axes |

||

|

SSCNET Communication (*1) |

Communication Type |

SSCNETIII/H,

SSCNETIII |

|||

|

Number of Lines |

2 lines (*2) |

1 line (*2) |

|||

|

Distance Between Stations

(Maximum) m (ft) |

SSCNETIII/H |

100 (328.08) |

|||

|

SSCNETIII |

50 (164.04) |

||||

|

Combined Cable Length (Maximum) m

(ft) |

SSCNETIII/H |

1600 (5249.30) |

|||

|

SSCNETIII |

800 (2624.70) |

||||

|

Number of SSCNETIII/H Head Module

Connection Stations |

Up to 8 stations

(Up to 4 stations/line) |

Up to 4 stations |

|||

|

Number of Optical Hub Unit

Connections |

Up to 32 units

(Up to 16 units/line) |

Up to 16 units |

|||

|

PERIPHERAL I/F (Ethernet) |

Data Transmission Speed |

100Mbps/10Mbps |

|||

|

Communication Mode |

Full-duplex/Half-duplex

(*3) |

||||

|

Transmission Method |

Base band |

||||

|

Cable Length (Maximum) m (ft) |

30 (98.43) |

||||

|

Memory Card Slot |

SD/SDHC memory

card compatible |

||||

|

Memory Capacity |

Standard ROM |

12MB |

|||

|

SD Memory Card |

Memory card

capacity (Up to 32B) |

||||

|

Number of Stages of Extension Base |

Up to 7 stages |

||||

|

Internal Current Consumption 5VDC

(A) |

1.20 |

||||

|

Weight (kg) |

0.28 |

||||

|

Dimensions mm (inch) (H x W x D) |

106.0 x 27.8 x

110.0 (4.17 x 1.09 x 4.33) |

||||

Notes:

1. Servo amplifier

(MR-J4-_B-LL) only.

2. Servo amplifier

(MR-J4-_B-RJ) only.

3. Servo amplifier

(MR-J3-_B/MR-J4-_B) only.

|

Model Number |

R64MTCPU |

R32MTCPU |

R16MTCPU |

|

|

Operation Cycle (Default) |

0.222ms/ 1 to 2

axes |

0.222ms/ 1 to 2

axes |

0.222ms/ 1 to 2

axes |

|

|

Interpolation Functions |

Linear

interpolation (Up to 4 axes), Circular interpolation (2 axes), Helical

interpolation (3 axes) |

|||

|

Control Modes |

PTP (Point to

Point) control, Speed control, Speed-position switching control, Fixed-pitch

feed, Continuous trajectory control, Position follow-up control, Speed

control with fixed position stop, High-speed oscillation control,

Speed-torque control, Pressure control (*1), Advanced synchronous control,

Machine control |

|||

|

Acceleration/Deceleration Control |

Trapezoidal

acceleration/deceleration, S-curve acceleration/deceleration, Advanced

S-curve acceleration/deceleration |

|||

|

Compensation |

Backlash

compensation, Electronic gear, Phase compensation |

|||

|

Programming Language |

Motion SFC,

Dedicated instruction |

|||

|

Servo Program Capacity |

32k steps |

|||

|

Number of Positioning Points |

6400 points

(Positioning data can be designated indirectly) |

|||

|

Peripheral I/F |

PERIPHERAL I/F |

|||

|

Home Position Return Function |

Proximity dog

method (2 types), Count method (3 types), Data set method (2 types), Dog

cradle method, Stopper method (2 types), Limit switch combined method, Scale

home position signal detection method, Dogless home position signal reference

method, Driver home position return method. Home position return re-try

function provided, home position shift function provided |

|||

|

JOG Operation Function |

Provided |

|||

|

Manual Pulse Generator Operation

Function |

Possible to

connect 3 modules (High-speed counter module use) |

|||

|

Synchronous Encoder Operation

Function |

Possible to

connect 12 modules (Via module (High-speed counter module use) + Via servo

amplifier (*2) + Via device + Multiple CPU advanced synchronous control) |

|||

|

M-Code Function |

M-code output

function provided, M-code completion wait function provided |

|||

|

Limit Switch Output Function |

Number of output

points 64 points x 2 settings Output timing compensation. Watch data: Motion

control data/Word device |

|||

|

ROM Operation Function |

Provided |

|||

|

Multiple CPU Advanced Synchronous

Control |

Provided |

|||

|

External Input Signal |

External input

signals (FLS/RLS/DOG) of servo amplifier, Bit device |

|||

|

Forced Stop |

Motion controller

forced stop (Device), Forced stop terminal of servo amplifier |

|||

|

Number of I/O Points |

Total 4096 points |

|||

|

Mark Detection Function |

Mark Detection Mode Setting |

Continuous

detection mode, Specified number of detection mode, Ring buffer mode |

||

|

Mark Detection Signal |

High-speed input

request signal (bit device, input signal of servo amplifier (DI1 to DI3) |

|||

|

Mark Detection Setting |

64 settings |

|||

|

Clock Function |

Provided |

|||

|

Security Function |

Provided |

|||

|

All Clear Function |

Provided |

|||

|

Remote Operation |

Remote RUN/STOP |

|||

|

File Management Function |

Available for

program and parameter data, cam data, label data, sampling data etc. |

|||

|

Optional Data Monitor Function |

SSCNETIII/H |

Up to 14

data/axis (Communication data: Up to 6 points/axis) |

||

|

SSCNETIII |

Up to 14

data/axis (Communication data: Up to 3 points/axis) |

|||

|

Digital Oscilloscope Function |

Motion buffering

method (Real-time waveform can be displayed). Sampling data: Word 16CH, Bit

16CH. Offline sampling |

|||

|

Absolute Position System |

Compatible by

setting battery to servo amplifier. (Possible to select the absolute data

method or incremental method for each axis) |

|||

|

Driver Communication Function (*3) |

Provided |

|||

|

File Transmission at Boot Function |

Provided |

|||

|

Parameter Change Function |

Provided |

|||

|

Event History Function |

Provided |

|||

|

Add-on Function |

Provided |

|||

|

Override Function |

Provided |

|||

|

Vibration Suppression Command

Filter |

Provided |

|||