Industrial Robot

MELFA FR SERIES

Evolved intelligence realizes advances in work procedures, cooperation between people and robots, and e-F@ctory-compatibility, making next-generation manufacturing a reality.

With globalization and increasingly diverse consumer needs in the market, the manufacturing industries face a time of considerable change.

It is no longer enough for industrial robots to simply perform a single task. Industry now demands robots with the capacity and flexibility to readily take on more sophisticated tasks.

The MELFA FR series provides new, more intelligent solutions that underpin "next-generation manufacturing", offering a simpler approach to advanced and flexible production. These robots can handle all your automation needs.

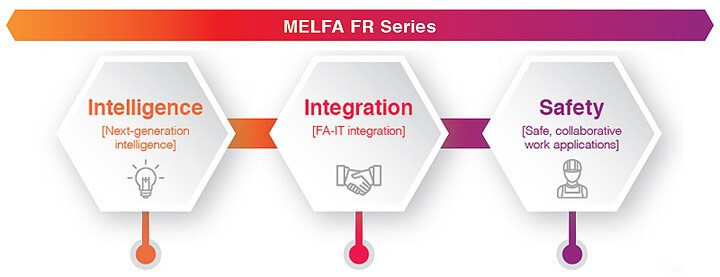

| MELFA FR series |

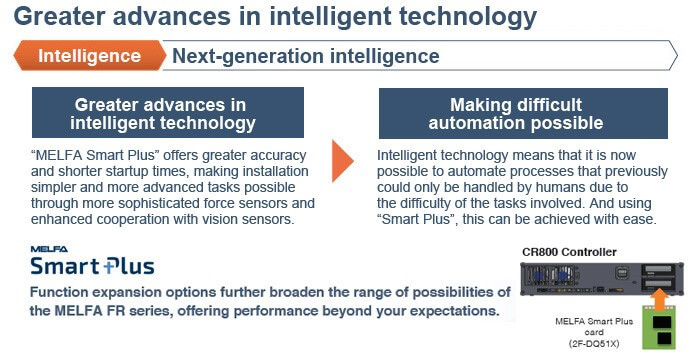

"Next-generation intelligent functions" make it simple to carry out work that has always defied automation.

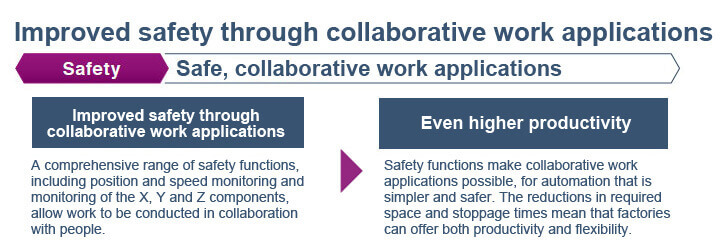

"Safe, collaborative work applications" allow robots and people to work together with high levels of safety.

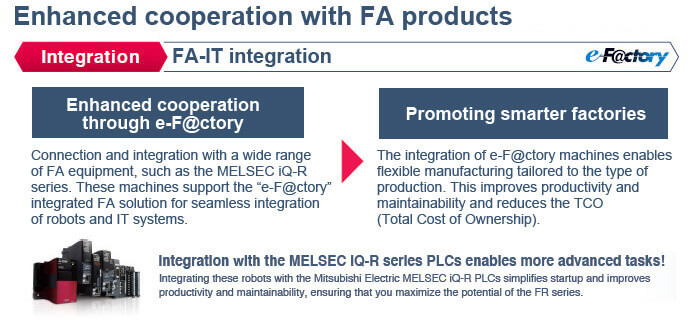

"FA-IT integration functions" support next generation manufacturing.

With these 3 key features, the FR Series is capable of handling virtually all your automation needs.

| |

| |

| |

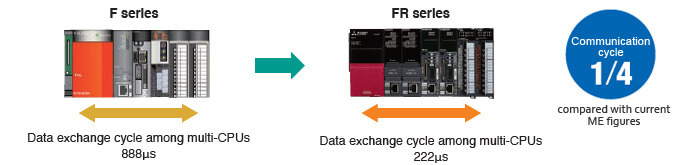

| Improved controller performance |

Control cycles on FR series controllers take just half the current time, improving robot control performance.

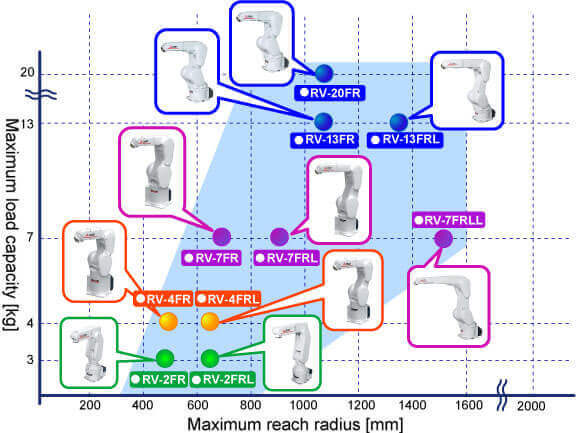

| MELFA FR series (Vertical Type) |

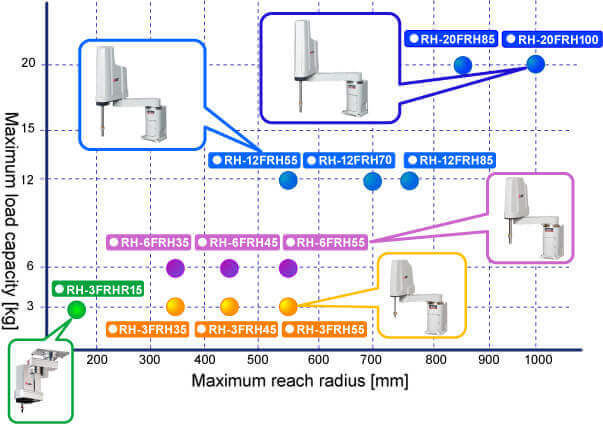

| MELFA FR series (Horizontal Type) |

|

Model Number |

RV2FR |

RV2FRL |

RV4FR |

RV4FRL |

RV7FR |

RV7FRL |

RV7FRLL |

RV13FR |

RV13FRL |

RV20FR |

|

|

Maximum Load Capacity (kg) |

2 |

2 |

4 |

4 |

7 |

7 |

7 |

13 |

13 |

20 |

|

|

Maximum Reach Radius (mm) |

504 |

649 |

515 |

649 |

713 |

908 |

1,503 |

1,094 |

1,388 |

1,094 |

|

|

Environmental Specifications |

Standard |

IP30 |

IP40 |

||||||||

|

Oil Mist |

– |

IP67 |

|||||||||

|

Cleanroom |

– |

ISO class3 |

|||||||||

|

Controller |

CR800-R, CR800-D |

||||||||||

Through Wrist

Wiring/Piping Options (RVFR Series)

Tooling Device

Configuration (4kg – 20kg)

|

Hand Configuration |

Wiring Format |

Robot Specifications |

Required Device |

Remarks |

|

|

External Wiring Set for the

Forearm |

External Wiring Set for the Base |

||||

|

Air-Hand + Hand Input Signal |

Interior

equipment |

SHxx01 |

- (*1) |

- |

Air hoses: Up to

2 systems |

|

Exterior

equipment |

Standard |

- (*2) |

- |

Air hoses: Up to

4 systems |

|

|

Hand Input Signal + Ethernet +

Force Sensor OR Electric Hand (*3, *4) |

Interior

equipment |

-SHxx02 |

- (*1) |

1F-HA01S-01

(Included) |

|

|

Exterior

equipment |

Standard |

1F-HB01S-01 |

1F-HA01S-01 |

Air hoses: Up to 4

systems |

|

|

Electric Hand + Ethernet |

Interior

equipment |

-SHxx03 |

- (*1) |

1F-HA02S-01

(Included) |

|

|

Exterior

equipment |

Standard |

1F-HB02S-01 |

1F-HA02S-01 |

||

|

Air-Hand + Hand Input Signal +

Force Sensor |

Interior equipment |

-SHxx04 |

- (*1) |

1F-HA01S-01

(Included) |

Air hoses: Up to

1 system |

|

Exterior

equipment |

Standard |

1F-HB01S-01 |

1F-HA01S-01 |

Air hoses: Up to

4 systems |

|

|

Air-Hand + Hand Input Signal +

Ethernet |

Interior

equipment |

-SHxx05 |

- (*1) |

1F-HA01S-01

(Included) |

Air hoses: Up to

1 system |

|

Exterior

equipment |

Standard |

1F-HB01S-01 |

1F-HA01S-01 |

Air hoses: Up to

4 systems |

|

Notes:

1. For internal

routing. (Pneumatics sold separately)

2. For external

routing. (Hoses, input cables and solenoid valves sold separately)

3. For SHxx02

configuration, the Air hand and Electric hand cannot be used simultaneously.

4. For SHxx02

configuration, the Force sensor and Electric hand cannot be used

simultaneously.

RVFR Series Part

Number Configuration

RV2FR • RV2FRL

|

Model Number |

RV2FR(B) |

RV2FRL(B) |

|

|

Environmental Specifications |

Standard |

||

|

Protection Degree |

IP30 |

||

|

Installation |

Floor type, ceiling type,

(wall-mounted type) (*2) |

||

|

Structure |

Vertical, multiple-joint type |

||

|

Degrees of Freedom |

6 |

||

|

Drive System (*1) |

AC servo motor (J2, J3 and J5:

with brake) |

||

|

Position Detection Method |

Absolute encoder |

||

|

Maximum Load Capacity (Rating) kg |

Maximum 3 (Rated 2) (*5) |

||

|

Arm Length (mm) |

230 + 270 |

310 + 335 |

|

|

Maximum Reach Radius (mm) |

504 |

649 |

|

|

Operating Range (deg) |

J1 |

480 (±240) |

|

|

J2 |

240 (±120) |

237 (-117 to +120) |

|

|

J3 |

160 (-0 to +160) |

||

|

J4 |

400 (±200) |

||

|

J5 |

240 (±120) |

||

|

J6 |

720 (±360) |

||

|

Maximum Speed (deg/sec) |

J1 |

300 |

225 |

|

J2 |

150 |

105 |

|

|

J3 |

300 |

165 |

|

|

J4 |

450 |

412 |

|

|

J5 |

450 |

||

|

J6 |

720 |

||

|

Maximum Composite Speed (mm/sec)

(*3) |

4955 |

4200 |

|

|

Cycle Time (sec) (*4) |

0.6 |

0.7 |

|

|

Position Repeatability (mm) |

±0.02 |

||

|

Ambient Temperature (°C) |

0 to 40 |

||

|

Weight (kg) |

19 |

21 |

|

|

Tolerable Moment (Nm) |

J4 |

4.17 |

|

|

J5 |

4.17 |

||

|

J6 |

2.45 |

||

|

Tolerable Amount of Inertia (kgm²) |

J4 |

0.18 |

|

|

J5 |

0.18 |

||

|

J6 |

0.04 |

||

|

Tool Wiring |

Gripper: 4 input points/4 output

points; Signal cable for the multi-function gripper |

||

|

Tool Pneumatic Pipes |

ø4 x 4 (Base to forearm section) |

||

|

Machine Cable |

5m (connector on both ends) |

||

|

Connected Controller |

CR800-D (iQ-R

functionality supported via optional 4F-R16RTCPU and software setting change) |

||

Notes:

1. The standard model

does not have a brake on the J1, J4, or J6 axis. There are models available

with brakes included for all axes.

2. The wall-mounted

specification is a custom specification where the operating range of the

J1-axis is limited.

3. This is the value

at the surface of the mechanical interface when all axes are composited.

4. The cycle time is

based on back-and-forth movement over a vertical distance of 25 mm and

horizontal distance of 300 mm when the load is 1 kg.

5. The maximum load

capacity indicates the maximum payload when the mechanical interface is facing

downward (±10° to the perpendicular).

RV4FR • RV4FRL

|

Model Number |

RV4FRM/C |

RV4FRLM/C |

|

|

Environmental Specifications |

Standard / Oil Mist / Cleanroom |

||

|

Protection Degree |

IP40 (standard) / IP67 (oil mist)

(*1) / ISOclass3 (*6) |

||

|

Installation |

Floor type, ceiling type,

(wall-mounted type) (*2) |

||

|

Structure |

Vertical, multiple-joint type |

||

|

Degrees of Freedom |

6 (*8) |

||

|

Drive System (*1) |

AC servo motor |

||

|

Position Detection Method |

Absolute encoder |

||

|

Maximum Load Capacity (Rating) kg |

Maximum 4 (Rated 4) (*7) |

||

|

Arm Length (mm) |

235+275 |

310+335 |

|

|

Maximum Reach Radius (mm) |

515 |

649 |

|

|

Operating Range (deg) |

J1 |

480 (±240) |

|

|

J2 |

240 (±120) |

||

|

J3 |

161 (-0 to +161) |

164 (-0 to +164) |

|

|

J4 |

400 (±200) |

||

|

J5 |

240 (±120) |

||

|

J6 |

720 (±360) |

||

|

Maximum Speed (deg/sec) |

J1 |

450 |

420 |

|

J2 |

450 |

336 |

|

|

J3 |

300 |

250 |

|

|

J4 |

540 |

540 |

|

|

J5 |

623 |

623 |

|

|

J6 |

720 |

720 |

|

|

Maximum Composite Speed (mm/sec)

(*3) |

9027 |

9048 |

|

|

Cycle Time (sec) (*4) |

0.36 |

0.36 |

|

|

Position Repeatability (mm) |

±0.02 |

||

|

Ambient Temperature (°C) |

0 to 40 |

||

|

Weight (kg) |

39 |

41 |

|

|

Tolerable Moment (Nm) |

J4 |

6.66 |

|

|

J5 |

6.66 |

||

|

J6 |

3.96 |

||

|

Tolerable Amount of Inertia (kgm²) |

J4 |

0.2 |

|

|

J5 |

0.2 |

||

|

J6 |

0.1 |

||

|

Tool Wiring |

Gripper: 8 input points/8 output

points; Signal cable for the multi-function gripper and sensors; LAN × 1

<100 BASE-TX> (*5) |

||

|

Tool Pneumatic Pipes |

Primary: ø6 × 2 Secondary: ø4 × 8,

ø4 × 4 (from base portion to forearm) |

||

|

Machine Cable |

5m (connector on both ends) |

||

|

Connected Controller |

CR800-D (iQ-R functionality

supported via optional 4F-R16RTCPU and software setting change) |

||

Notes:

1. Please contact a

Mitsubishi Electric dealer since the environmental resistance may not be

secured depending on the characteristics of oil you use. Air will need to be

purged from the lines. For details, refer to the specifications sheet.

2. The wall-mounted

specification is a custom specification where the operating range of the

J1-axis is limited.

3. This is the value

at the surface of the mechanical interface when all axes are composited.

4. The cycle time is

based on back-and-forth movement over a vertical distance of 25 mm and

horizontal distance of 300 mm when the load is 1 kg.

5. Can also be used as

a spare line (0.13 sq. mm, 4-pair cable) for conventional models.

6. Preservation of

cleanliness levels depends on conditions of a downstream flow of 0.3 m/s in the

cleanroom and internal robot suctioning. A ø8-mm coupler for suctioning is

provided at the back of the base.

7. The maximum load

capacity indicates the maximum payload when the mechanical interface is facing

downward (±10° to the perpendicular).

8. Please contact our

sales offices if you need a five axes long arm model.

RV7FR • RV7FRL •

RV7FRLL

|

Model Number |

RV7FRM/C |

RV7FRLM/C |

RV7FRLLM/C |

|

|

Environmental Specifications |

Standard / Oil Mist / Cleanroom |

|||

|

Protection Degree |

IP40 (standard) / IP67 (oil mist)

(*1) / ISO class3 (*6) |

|||

|

Installation |

Floor type, ceiling type,

(wall-mounted type) (*2) |

|||

|

Structure |

Vertical, multiple-joint type |

|||

|

Degrees of Freedom |

6 |

|||

|

Drive System (*1) |

AC servo motor |

|||

|

Position Detection Method |

Absolute encoder |

|||

|

Maximum Load Capacity (Rating) kg |

Maximum 7 (Rated 7) (*7) |

|||

|

Arm Length (NO1 am) |

340 + 370 |

435+470 |

565+805 |

|

|

Maximum Reach Radius (mm) |

713 |

908 |

1503 |

|

|

Operating Range (deg) |

J1 |

480 (±240) |

380 (±190) |

|

|

J2 |

240 (-115 to +125) |

240 (-110 to +130) |

240 (-90 to +150) |

|

|

J3 |

156 (-0 to +156) |

162 (-0 to +162) |

167.5 (-10 to +157.5) |

|

|

J4 |

400 (±200) |

|||

|

J5 |

240 (±120) |

|||

|

J6 |

720 (±360) |

|||

|

Maximum Speed (deg/sec) |

J1 |

360 |

288 |

234 |

|

J2 |

401 |

321 |

164 |

|

|

J3 |

450 |

360 |

219 |

|

|

J4 |

337 |

337 |

375 |

|

|

J5 |

450 |

450 |

450 |

|

|

J6 |

720 |

720 |

720 |

|

|

Maximum Composite Speed (mm/sec)

(*3) |

11064 |

10977 |

15,300 |

|

|

Cycle Time (sec) (*4) |

0.32 |

0.35 |

0.63 |

|

|

Position Repeatability (mm) |

±0.02 |

±0.06 |

||

|

Ambient Temperature (°C) |

0 to 40 |

|||

|

Weight (kg) |

65 |

67 |

130 |

|

|

Tolerable Moment (Nm) |

J4 |

16.2 |

||

|

J5 |

16.2 |

|||

|

J6 |

6.86 |

|||

|

Tolerable Amount of Inertia (kgm²) |

J4 |

0.45 |

||

|

J5 |

0.45 |

|||

|

J6 |

0.10 |

|||

|

Tool Wiring |

Gripper: 8 input points, Signal

cable for the multi-function gripper, LAN × 1 <100 BASE-TX> (*5) |

|||

|

Tool Pneumatic Pipes |

Primary: ø6 × 2 Secondary: ø4 × 8,

ø4 × 4 (from base portion to forearm) |

Primary: ø6 × 2 Secondary: ø6 × 8,

ø4 × 4 (from base portion to forearm) |

||

|

Machine Cable |

5m (connector on both ends) |

|||

|

Connected Controller |

CR800-D (iQ-R functionality

supported via optional 4F-R16RTCPU and software setting change) |

|||

Notes:

1. Please contact

Mitsubishi Electric dealer since the environmental resistance may not be

secured depending on the characteristics of oil you use.

2. The wall-mounted

specification is a custom specification where the operating range of the

J1-axis is limited.

3. This is the value

at the surface of the mechanical interface when all axes are composited.

4. The cycle time is

based on back-and-forth movement over a vertical distance of 25 mm and

horizontal distance of 300 mm when the load is 1 kg.

5. Can also be used as

a spare line (0.13 sq. mm, 4-pair cable) for conventional models.

6. Preservation of cleanliness

levels depends on conditions of a downstream flow of 0.3 m/s in the cleanroom

and internal robot suctioning. A ø8-mm coupler for suctioning is provided at

the back of the base.

7. The maximum load

capacity indicates the maximum payload when the mechanical interface is facing

downward (±10° to the perpendicular).

RV13FR • RV13FRL

|

Model Number |

RV13FRM/C |

RV13FRLM/C |

RV20FRM/C |

|

|

Environment |

Standard / Oil Mist / Cleanroom |

|||

|

Protection Degree |

IP40 (standard), IP67 (oil mist)

(*1), ISO Class 3 (*6) |

|||

|

Mounting Position |

Floor type, ceiling type,

(wall-mounted type) (*2) |

|||

|

Structure |

Vertical, multiple-joint type |

|||

|

Degree of Freedom |

6 axis |

|||

|

Drive System |

AC servo motor |

|||

|

Position Detection Method |

Absolute encoder |

|||

|

Maximum Payload (Rated) kg |

Maximum 13 (Rated 12) (*7) |

Maximum 20 (Rated 15) |

||

|

Arm Length (mm) |

410 + 550 |

565 + 690 |

410 + 550 |

|

|

Maximum Reach Radius (mm) |

1,094 |

1,388 |

1,094 |

|

|

Operating Range (deg) |

J1 |

380 (±190) |

||

|

J2 |

240 (-90 to +150) |

|||

|

J3 |

167.5 (-10 to +157.5) |

|||

|

J4 |

400 (±200) |

|||

|

J5 |

240 (±120) |

|||

|

J6 |

720 (±360) |

|||

|

Maximum Speed (deg/sec) |

J1 |

290 |

234 |

110 |

|

J2 |

234 |

164 |

110 |

|

|

J3 |

312 |

219 |

110 |

|

|

J4 |

375 |

375 |

124 |

|

|

J5 |

375 |

375 |

125 |

|

|

J6 |

720 |

720 |

360 |

|

|

Synthetic Maximum Speed (mm/sec)

(*3) |

10,450 |

9,700 |

4200 |

|

|

Cycle Time (sec) (*4) |

0.53 |

0.68 |

0.70 |

|

|

Position Repeatability (mm) |

±0.05 |

|||

|

Ambient Temperature (°C) |

0 to 40 |

|||

|

Weight (kg) |

120 |

130 |

120 |

|

|

Allowable Movement (Nm) |

J4 |

19.3 |

49.0 |

|

|

J5 |

19.3 |

49.0 |

||

|

J6 |

11 |

11 |

||

|

Allowable Inertia (KGM2) |

J4 |

0.47 |

1.40 |

|

|

J5 |

0.47 |

1.40 |

||

|

J6 |

0.14 |

0.14 |

||

|

Tool Wiring |

Gripper: 8 input points/8 output

points; Signal cable for the multi-function gripper; LAN × 1 <100

BASE-TX> (*5) |

|||

|

Tool Pneumatic Pipes |

Primary: ø6 × 2 Secondary: ø6 × 8,

ø4 × 4 (from base portion to forearm) |

|||

|

Machine Cable |

5m (connector on both ends) |

|||

|

Connection Controller |

CR800-D (iQ-R functionality

supported via optional 4F-R16RTCPU and software setting change) |

|||

Notes:

1. Please contact

Mitsubishi Electric dealer since the environmental resistance may not be

secured depending on the characteristics of oil you use.

2. The wall-mounted specification

is a custom specification where the operating range of the J1-axis is limited.

3. This is the value

at the surface of the mechanical interface when all axes are composited.

4. The cycle time is

based on back-and-forth movement over a vertical distance of 25 mm and

horizontal distance of 300 mm when the load is 5 kg.

5. Can also be used as

a spare line (0.13 sq. mm, 4-pair cable) for conventional models. Provided up

to the inside of the forearm.

6. Preservation of

cleanliness levels depends on conditions of a downstream flow of 0.3 m/s in the

cleanroom and internal robot suctioning. A 8-mm coupler for suctioning is

provided at the back of the base.

7. The maximum load

capacity indicates the maximum payload when the mechanical interface is facing downward

(±10° to the perpendicular).