Horizontal Pillow Machine

This machine feeds a packaging film roll horizontally, wraps food supplied from the conveyor in pillow shape, and then seals and cuts the both ends.

System Level:

Concept Movie:

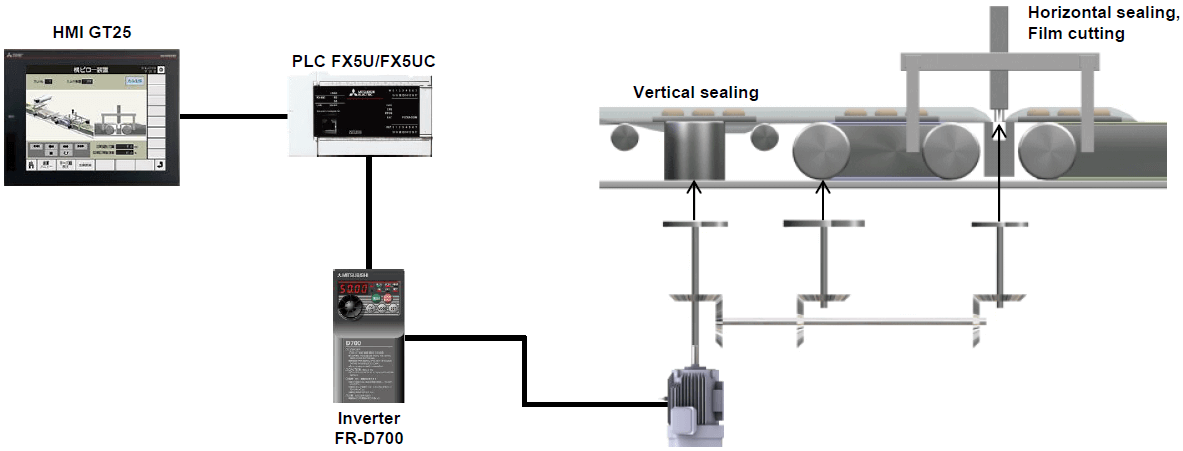

Basic System - Horizontal Pillow Machine

The rolls in each process (conveyor, vertical sealing, horizontal sealing) are mechanically interlocked and driven. The speed can be adjusted with an inverter, but the system operates at a constant speed. It is suitable for mass production of small varieties because the mechanical cam needs to be changed when the package specification is changed.

System Configuration:

Equipment:

| ProcessEquipment | Transport | Film wrapping | Film sealing | Film cutting | Suggested Model |

|---|---|---|---|---|---|

| Drive System | Inverter + Induction motor |

FR-D700 □K (Speed control) |

|||

| Controller | I/O or serial communication from PLC | FX5U/ FX5UC (Constant speed feed/ Tension control) |

|||

| Visualization | GT25 (Support GOT Drive function) |

||||

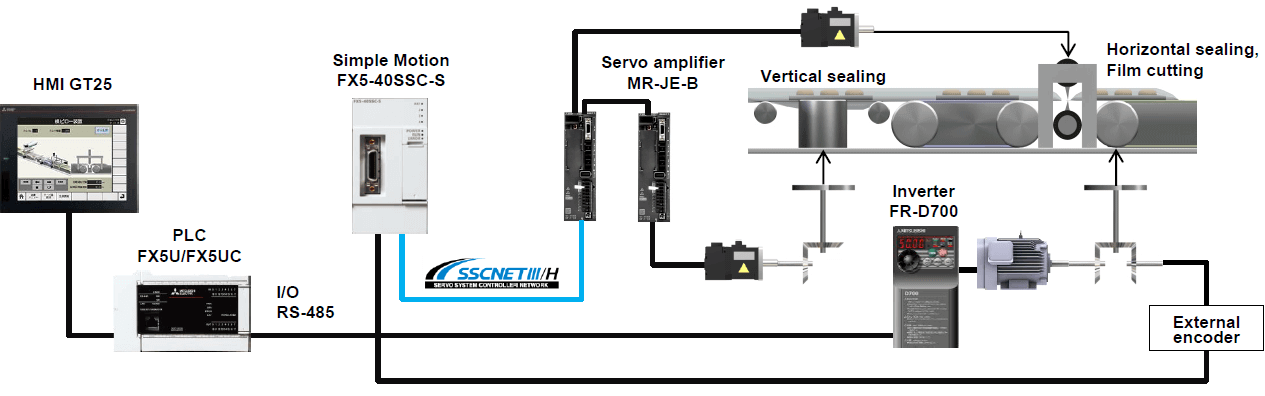

Intermediate System - Horizontal Pillow Machine

The rolls in each process are driven by independent motors and the processes are interlocked with electronic cams. All shafts are controlled by advanced synchronous control. Since the motion in each process can be flexibly changed by changing the cam pattern of simple motion, small-lot production of various products can be efficiently performed. In addition, program development efficiency can be improved by using the FBs of iQ Monozukuri PACKAGING.

System Configuration:

Equipment:

| ProcessEquipment | Transport | Film wraping | Film sealing/ | Film cutting | Suggested Model |

|---|---|---|---|---|---|

| Drive System | Inverter + Induction motor |

Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

FR-D700 □K (Speed control) MR-JE-□B (Advanced synchronous control) |

| Controller | I/O, serial communication, analog | Simple Motion module | FX5U/FX5UC FX5-40SSC-S |

||

| Required functions | Alignment feed | Tension control | Side seal: Rotary cutter Mark detection function |

iQ Monozukuri PACKAGING | |

| Visualization | GT25 (Support GOT Drive function) |

||||

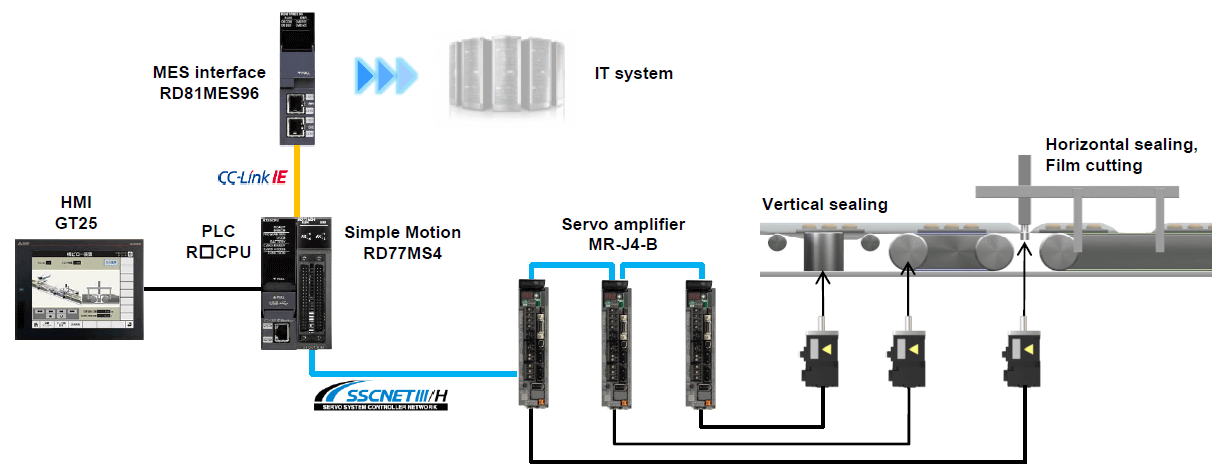

Advanced System - Horizontal Pillow Machine

By using the MES interface module in addition to the MIDDLE system, data in each process can be collected and managed in real time to realize IoT application in factories.

System Configuration:

Equipment:

| ProcessEquipment | Transport | Film wraping | Film sealing/ | Film cutting | Suggested Model |

|---|---|---|---|---|---|

| Drive System | Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

MR-J4-□B (Advanced synchronous control) |

| Controller | CPU + Simple Motion module + MES Interface module | R□CPU RD77MS4 RD81MES96(For IoT application) |

|||

| Required functions | Alignment feed | Tension control | Side seal: Rotary cutter Mark detection function |

iQ Monozukuri PACKAGING | |

| Visualization | GT25 (Support GOT Drive function) |

||||