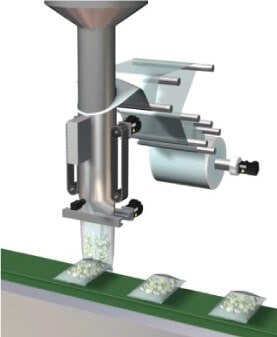

Vertical Pillow Machine

This machine feeds a packaging film roll vertically and forms a bag. After putting food in the bag, it seals and cuts the top of the bag.

System Level:

Concept Movie:

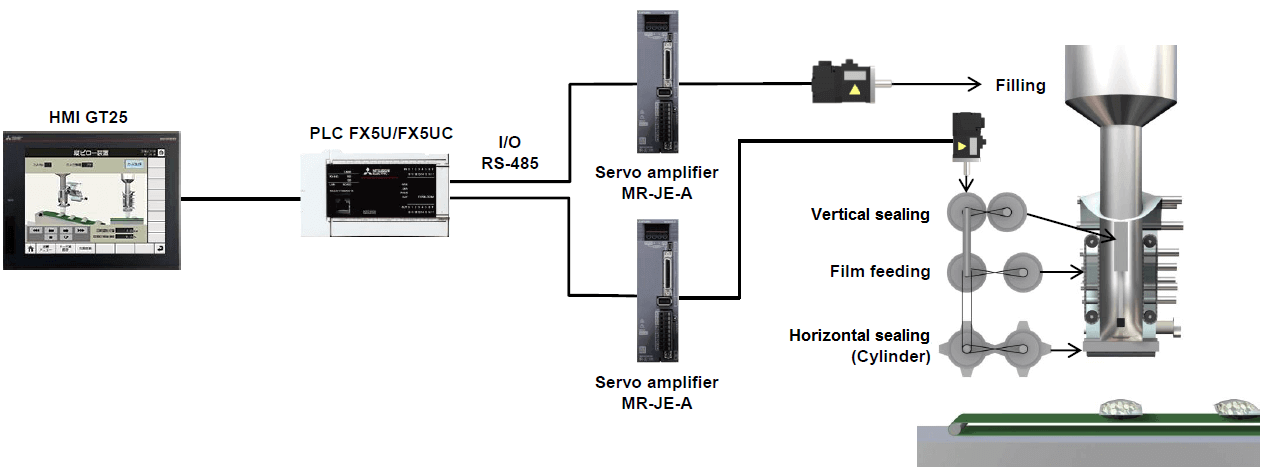

Basic System - Vertical Pillow Machine

Vertical sealing, film feeding, and horizontal sealing are mechanically interlocked and synchronized. Processes other than filling are performed by intermittent feed operation using a servo amplifier and a servo motor

System Configuration:

Equipment:

| ProcessEquipment | Filling | Film feeding/ Vertical film sealing |

Horizontal film sealing/ Film cutting |

Suggested Model |

|---|---|---|---|---|

| Drive System | Servo amplifier + Servo motor (Built-in positioning) |

Servo amplifier + Servo motor (Built-in positioning) |

MR-JE-□A |

|

| Controller | I/O or serial communication from PLC | FX5U/ FX5UC | ||

| Visualization | GT25 (Support GOT Drive function) |

|||

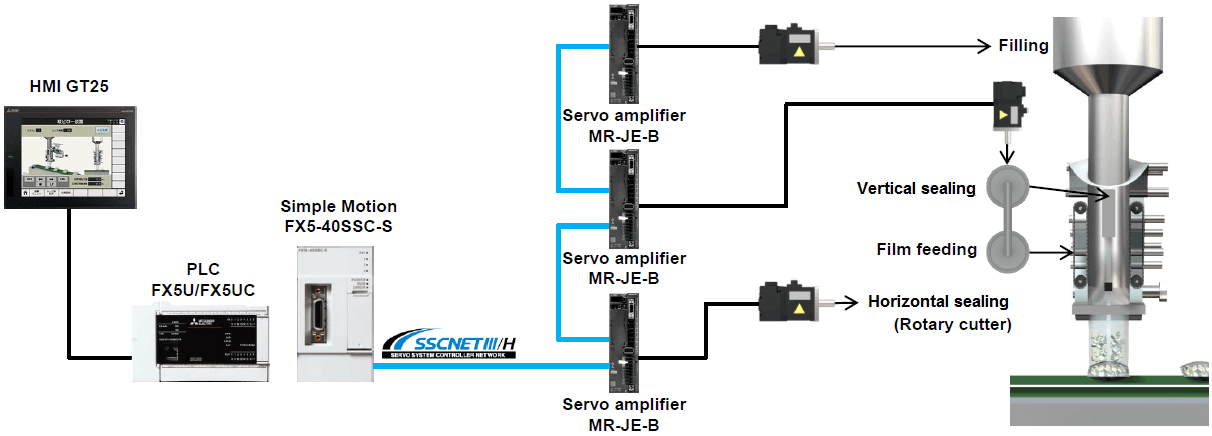

Intermediate System - Vertical Pillow Machine

Each process of filling, film feeding/vertical sealing, and horizontal sealing/film cutting are driven by different servo amplifiers and motors. Since the motion in each process can be flexibly changed by changing the cam pattern of simple motion, small-lot production of various products can be efficiently performed. In addition, program development efficiency can be improved by using the FBs of iQ Monozukuri PACKAGING.

System Configuration:

Equipment:

| ProcessEquipment | Filling | Film feeding/ Vertical film sealing |

Horizontal film sealing/ Film cutting |

Suggested Model |

|---|---|---|---|---|

| Drive System | Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

MR-JE-□B |

| Controller | PLC + Simple Motion module | FX5U-□M□/E□ FX5-40SSC-S |

||

| Required functions | Advanced synchronous control | Advanced synchronous control | - Rotary cutter - Mark detection function - Advanced synchronous control |

|

| Visualization | GT25 (Support GOT Drive function) |

|||

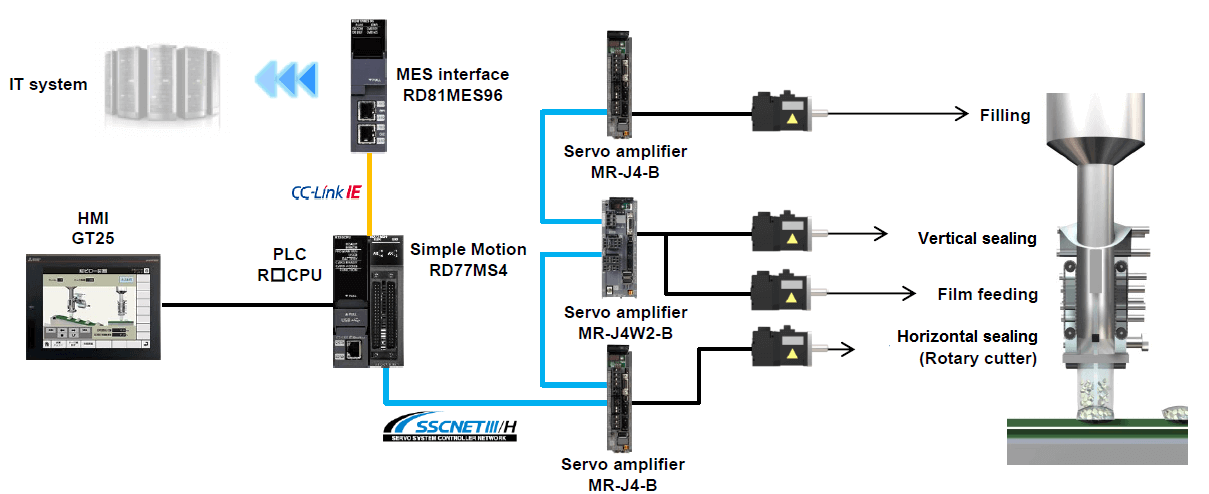

Advanced System - Vertical Pillow Machine

By using the MES interface module in addition to the MIDDLE system, data in each process can be collected and managed in real time to realize IoT application in factories.

System Configuration:

Equipment:

| ProcessEquipment | Filling | Film feeding/ Vertical film sealing |

Horizontal film sealing/ Film cutting |

Suggested Model |

|---|---|---|---|---|

| Drive System | Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

Servo amplifier + Servo motor |

MR-JE-□B |

| Controller | PLC + Simple Motion module + MES Interface module | R□CPU RD77MS4 RD81MES96 (For IoT applications) |

||

| Required functions | Advanced synchronous control | Advanced synchronous control | - Rotary cutter - Mark detection function - Advanced synchronous control |

|

| Visualization | GT25 (Support GOT Drive function) |

|||