Energy Saving with Inverters

Motors are used everywhere in our daily life. For example, Motors are used for:

- Air-conditioning equipments (for buildings, shopping centers, factories, etc.)

- Elevators/ escalators

- Machine tools

- Conveyor

- Automated car parks

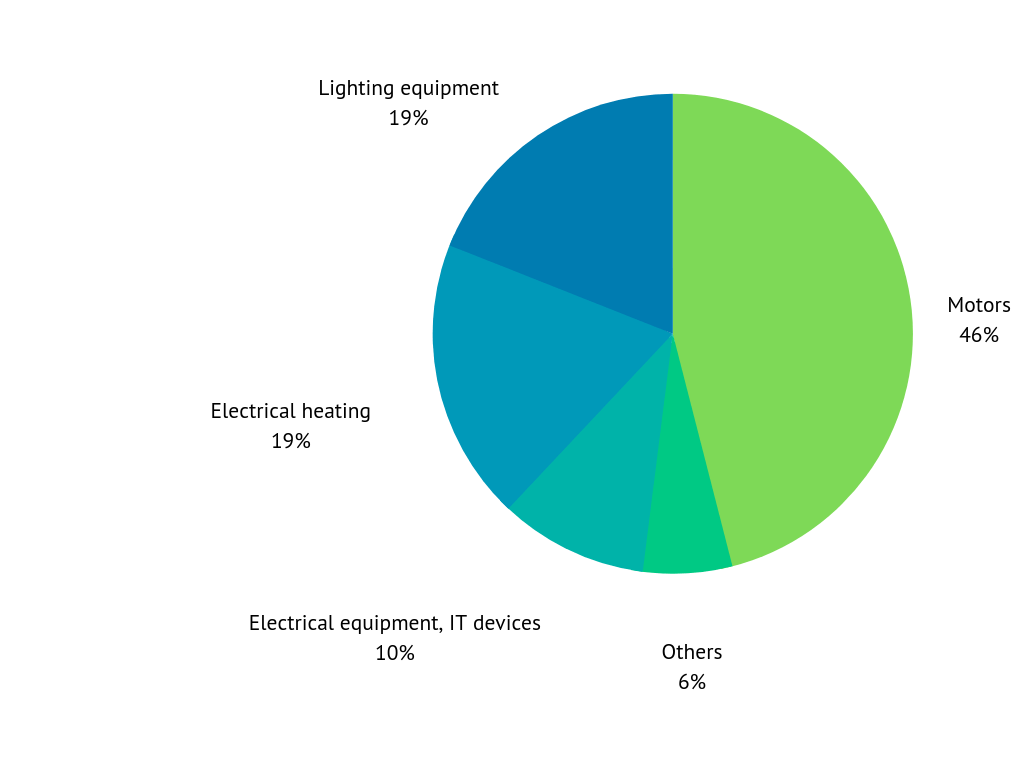

Since motors are used for many different types of equipment, the energy consumed by electric motor systems accounts for 46& of world's energy consumption. (About 55% in Japan)

If all the motors currently being used were replaced with energy-saving motors, the energy consumption would be far lower than it is today!

Shares of World Energy Consumption (21.4 trillion kWh in 2010)

Source: MOTOR SUMMIT 2012 - Key World Energy Statistics 2012

Utilizing the motor capability to the full

Optimum excitation control continuously adjusts the excitation current to an optimum level to provide the highest motor efficiency. With a small load torque, a substantial energy saving can be achieved.

For example, at 4% motor load torque for a general-purpose motor, the motor efficiency under Optimum excitation control is about 30% higher than the motor efficiency under V/F control.

Air volume control by controlling motor speed

The air volume is controlled by the motor speed, which can be reduced by lowering the output frequency.

Reducing the air volume will lead to large energy savings.

Why can inverter-driven motors save energy?

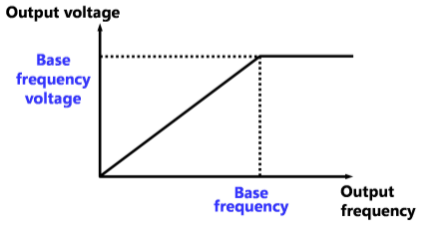

When a motor is driven by an inverter at a medium speed, the voltage is reduced in proportion to the motor speed regardless of the current flow. This contributes to energy saving. It can be said that in any application, driving a variable-speed motor with an inverter can reduce the energy consumption.

This means that driving a variable-speed motor with an inverter can save far more energy than driving a standard motor with a commercial power supply and applying brakes to reduce its speed to a medium speed.