Product Features

Features of the new product

It will introduce three of the features of the latest model M800/M80 Series.

Faster, smoother, easier with higher accuracy!

Minimize the life cycle cost for end users!

Basic PerformanceMITSUBISHI's unique CNC-dedicated CPU

CNC-dedicated CPU

CNC-dedicated CPU with MITSUBISHI’s own ultra-high-speed processing capacity of the state-of-the-art process technology

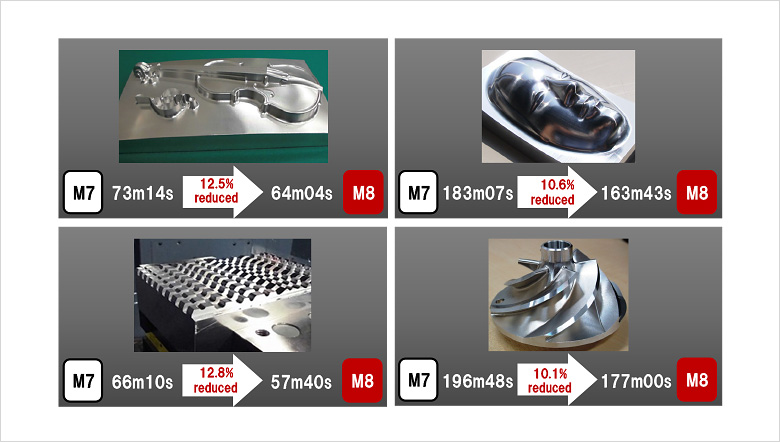

Machining PerformanceAchieve a reduction of processing time (our M7 series ratio)

Advanced DesignRealized the innovative operability with touch panel

the Good Design Award in FY 2015

Productivity

Machining CenterSuper Smooth Surface control

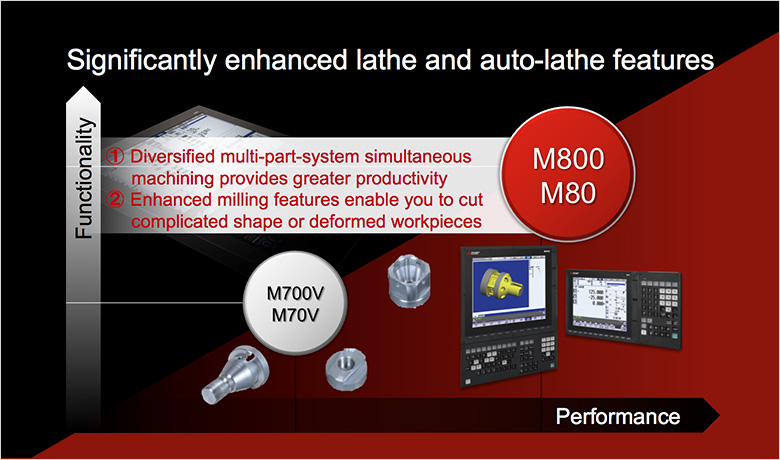

LatheSignificantly enhanced lathe and auto-lathe features

Operability

The operability in the new touch panel of the latest model M800/M80 series, will introduce in the video.

Please click the Play button.

Reliability

Enhanced environment resistance and maintainability for each unit

Control Unit

- ECC-embedded memory

- No-fan structure

- Instantaneous power failure detecting function

Display Unit

- SD and USB I/Fs are separated

- Capacitive touch-screen panel

- LED for back light

I/O Unit

- RIO2.0 communication

- Enhanced noise immunity

- DIN rail attachable

Personal Computer Unit

- No hard-disk drive (Vibration resistance improved)

Connectivity

IoT/Response to the Era of Big Data

NC Visualizer enables to visualize the operating status of machine tools easier.

- To build the "Operation monitoring system", install NC Visualizer, an operation monitoring application, to your server PC.

NC Visualizer displays the machine tool's status such as "operating", "stopped", "alarm", and "power OFF" in a list, which helps operators to improve the productivity or to analyze the cause of alarms.

In addition, the operators can monitor the operating status with an external PC/tablet PC via a Web browser.

Maintenance

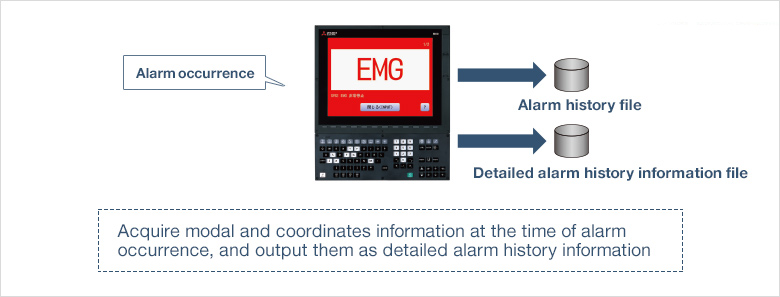

Detailed alarm history information

At the time of alarm occurrence, the detailed information of alarm history is output in a separate file from the existing alarm history.

Understanding detailed information such as modal and coordinates at the time of occurrence enables you to perform early troubleshooting.

Safety

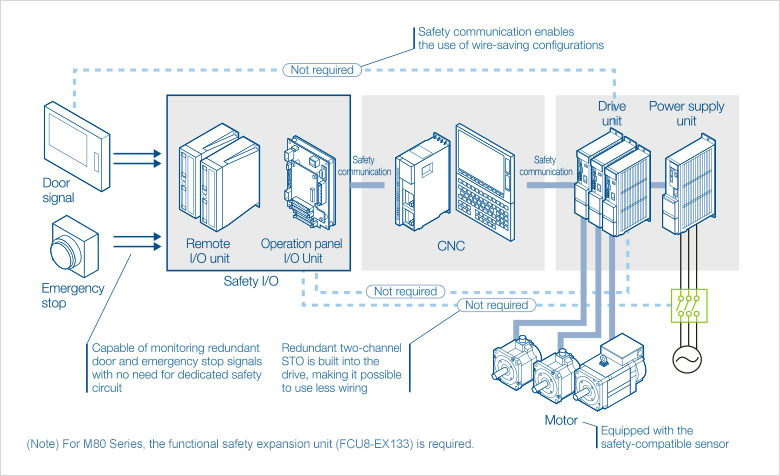

M800/M80 Series provides a range of safety features collectively called the Smart Safety Observation Function.

This function has achieved full conformity with the safety standards that cover the entire system including CNC, drive, I/O, sensors and communication.

Smart safety observation function

- - Safety-related I/O observation

- - Safely-Limited Speed (SLS)

- - Safe Operating Stop (SOS)

- - Safe Brake Control/Safe Brake Test (SBC/SBT)

- - Safe Stop (SS1/SS2)

- - Emergency stop observation

- - Safely-Limited Position (SLP)

- - Safe Speed Monitor (SSM)

- - Safe Cam (SCA)

- - Safe Torque Off (STO)

Functional safety system can be configured easily.