Product Features

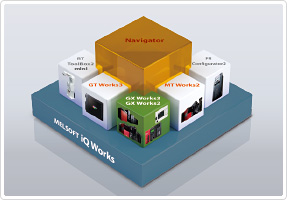

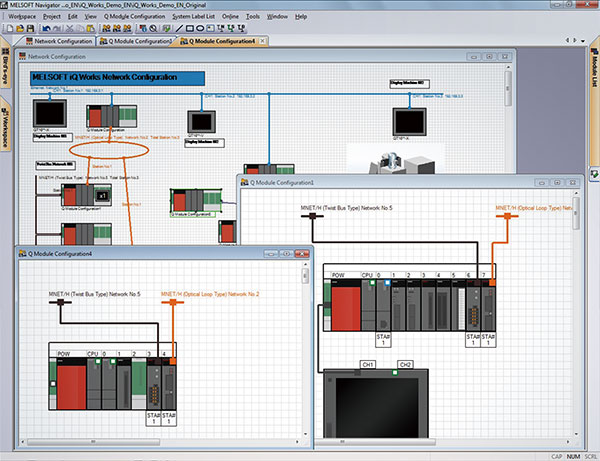

MELSOFT iQ Works is an integrated software suite consisting of GX Works3, MT Works2, GT Works3, RT ToolBox3 mini, FR Configurator2 which are programming software for each respective product. Integration is further enhanced with MELSOFT Navigator as the central system configuration incorporating an easy‑to‑use, graphical user interface with additional project-sharing features such as system labels and parameters. The advantages of this powerful integrated software suite are that system design is made much easier with a substantial reduction in repetitious tasks, cutting down on errors while helping to reduce the overall TCO.

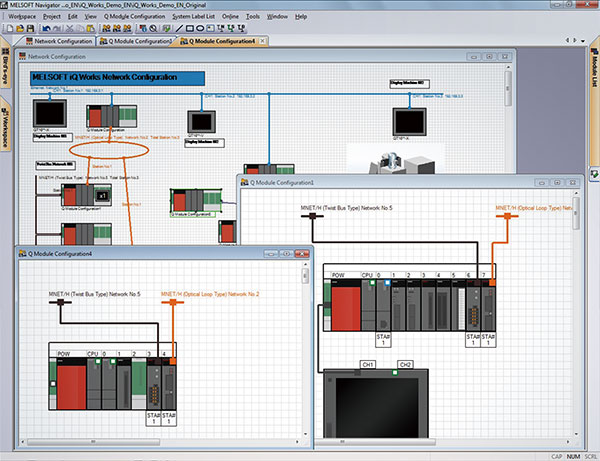

System management software

MELSOFT Navigator, along with GX Works3, GX Works2, MT Works2, GT Works3, RT ToolBox3 mini, FR Configurator2, facilitates system level design and acts as the interface between each software. Useful functions include design of system configuration, parameter batch setting, system labels, and batch read.

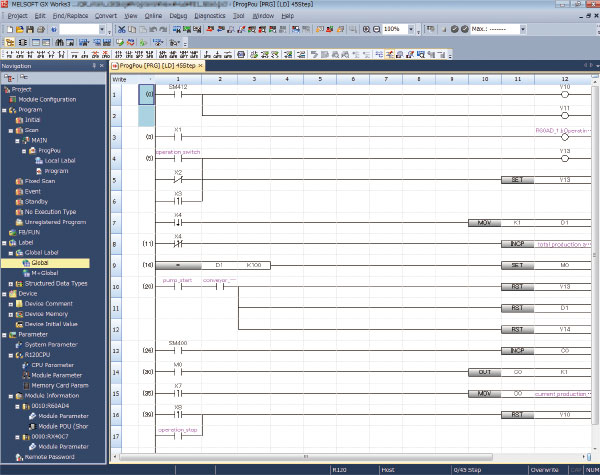

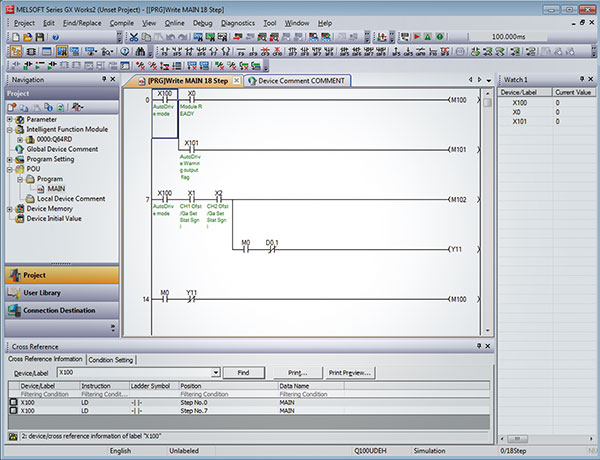

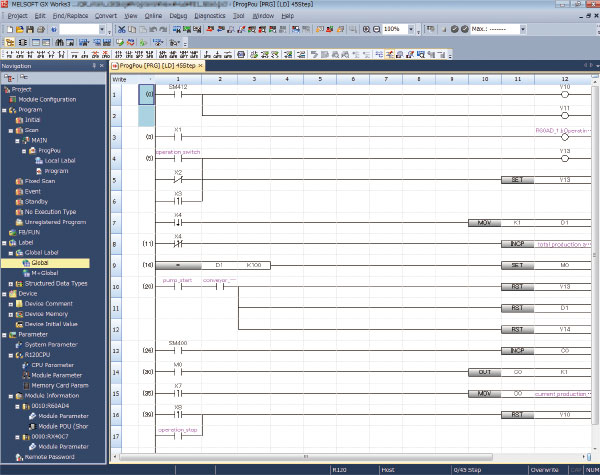

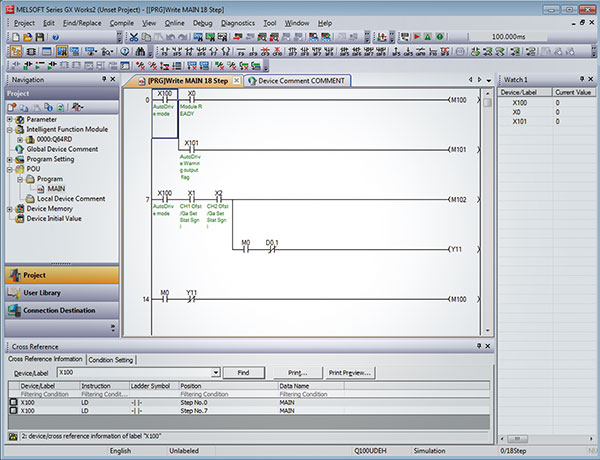

Programmable controller engineering software

Graphical and intuitive operability, easy programing by just "selecting", and diagnosis function for easy troubleshooting reduces engineering cost.

Incorporating legacy support of programs created with GX Developer, further improving its functionality resulting in reduced engineering costs.

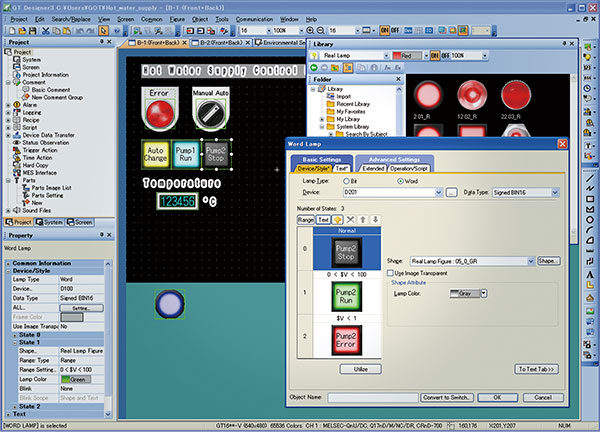

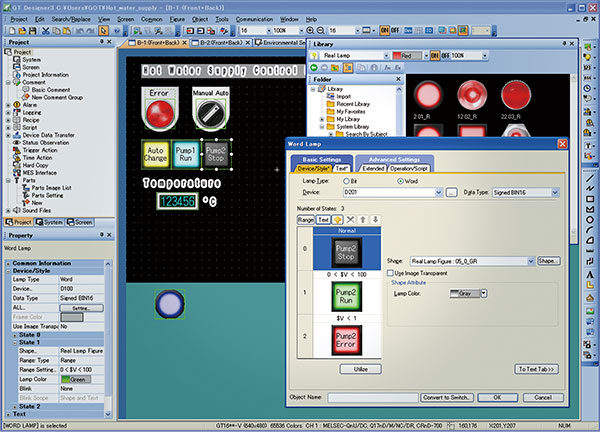

HMI/GOT screen design software

The GOT (Graphic Operation Terminal) screen creation software has been designed with 3 main features; Simplicity, Graphic Design, and Easy-Usability, further helping to create graphic screens with fewer steps.

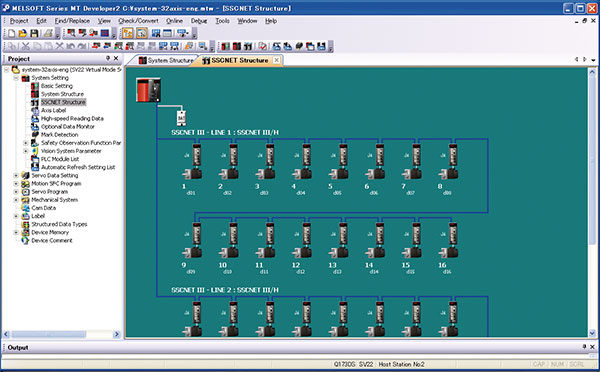

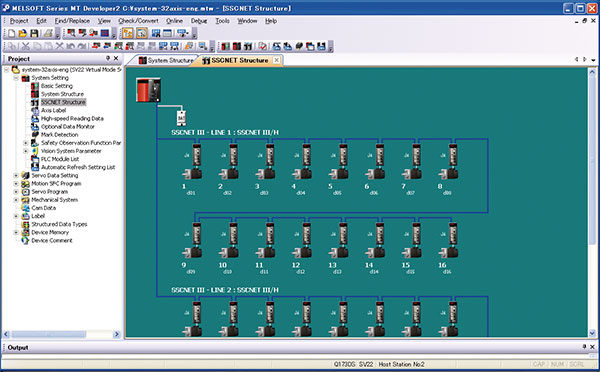

Motion controller engineering software

The motion control design and maintenance software includes intuitive graphic based programming together with a digital oscilloscope simulator.

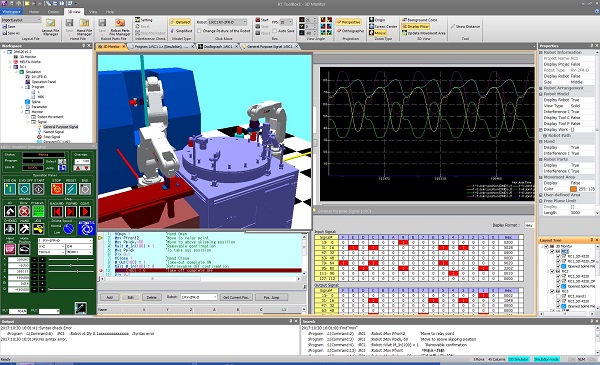

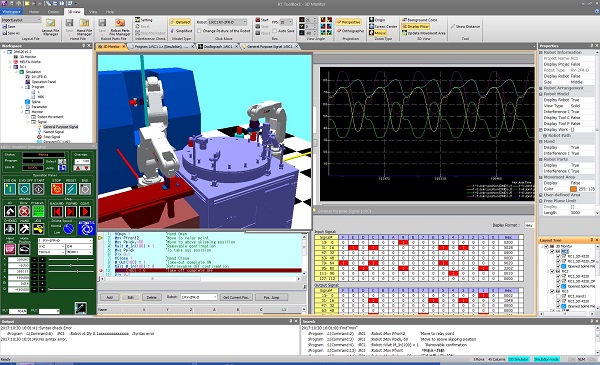

Robot engineering software

Supports various steps from programming, to commissioning, evaluation, and maintenance. In addition, improved preventative maintenance is realized through the use of an integrated 3D robot simulator.

* RT ToolBox3 mini (simplified version) will be installed if iQ Works product ID is used. When RT ToolBox3 (with simulation function) is required, please purchase RT ToolBox3 product ID.

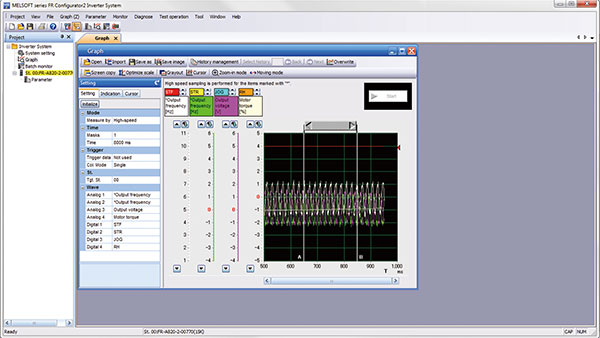

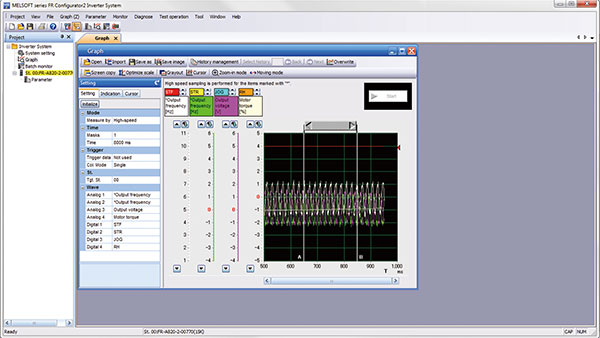

Inverter setup software

This software simplifies the setup and maintenance of AC Inverters. Parameters can be registered easily and distributed to multiple inverters when replacing, and activation of the PLC function all from one setup screen.

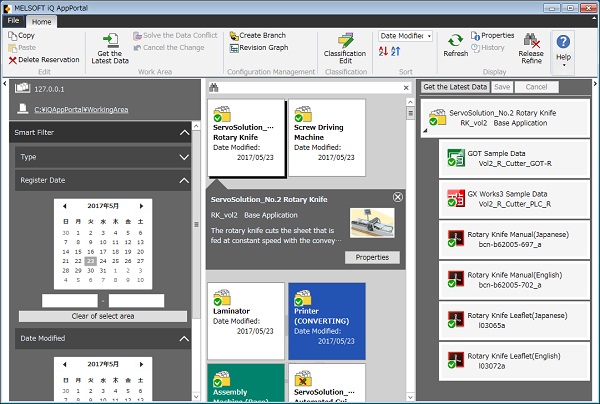

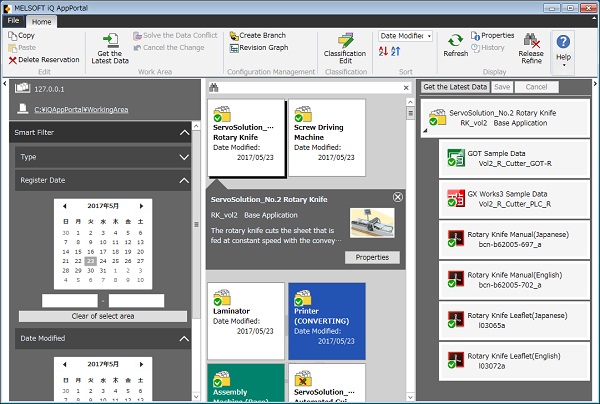

Application Integrated Management Software

It is the software for which the assets such as project and library are managed by the purpose. The revisions of registered assets are accumulated and it is easy to get the past assets. The purpose assets can be found quickly by filtering.

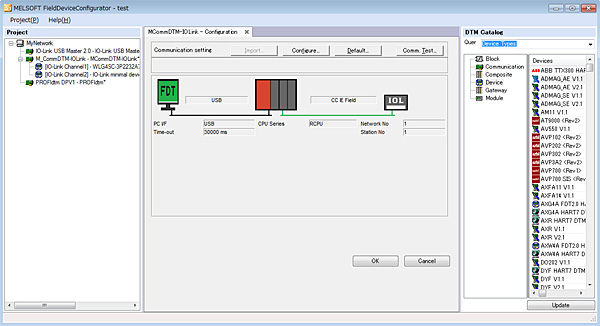

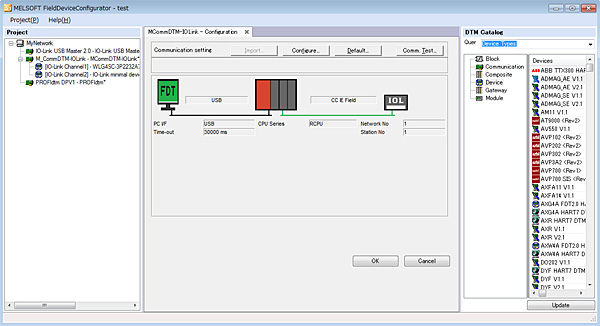

Field Device tool

A Field Device managing/setting software which is MITSUBISHI ELECTRIC products and it is corresponding to FDT/DTM open specification.

And it can be used as a FDT frame application to set the parameters of Field Device, or to maintain/adjust the device.