Product Features

MELFA-3D Vision enhancement function

AI automatically adjusts 3D vision sensor parameters. Set-up is simple.

(Automatic parameter setting with AI : only when model-less recognition is used)

For details on this function, please refer to the catalog "MELFA Smart Plus".

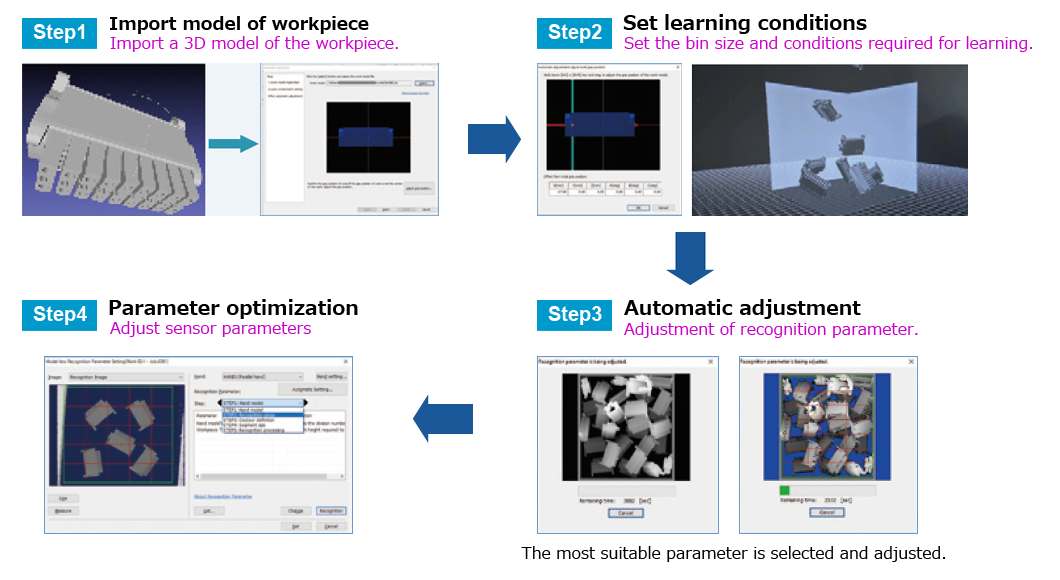

Automatic parameter setting with AI

Sensor parameter adjustment which requires a high level of specialist knowledge is automated with our proprietary AI technology. Anyone can adjust parameters quickly and easily just like a pro.

*This optional function is supported with the options MELFA-3D Vision 2.0 and 3.0.

*This function is available only when model-less recognition is used.

MELFA-3D Vision3.0 features

MELFA-3D Vision 3.0 is software that connects a compact 3D vision sensor for robots to measure and recognize parts. It uses a camera head that can measure distances, which allows it to take the dimensions of randomly stacked parts and recognize them.

*This camera head is supplied by customer.

*The only models that support MELFA Smart Plus are the N35-804-16-IR, N35-806-16-IR,and N35-808-16-IR.

Supported robots

| Robot Type | Robot controller | RT ToolBox3 |

|---|---|---|

| FR series, CR series | CR800-D/R/Q Ver.A3 or later. | Ver.1.82L or later |

Set-up procedure

*Note) Model-less recognition does not usually require a 3D model. However, a 3D model of the workpiece is required for this function.

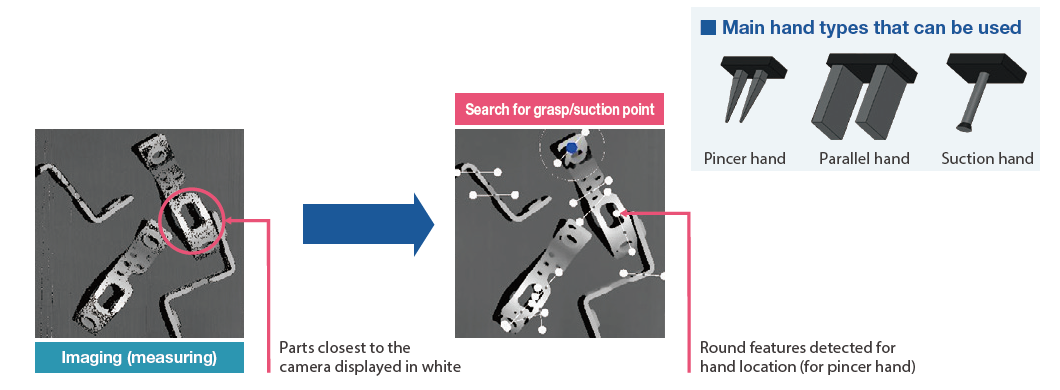

Model-less recognitiong

Model-less recognition is a method used to pick up the workpiece by finding a place on the workpiece where the hand tool can grasp or apply suction to. This means that there is no need to register a workpiece.

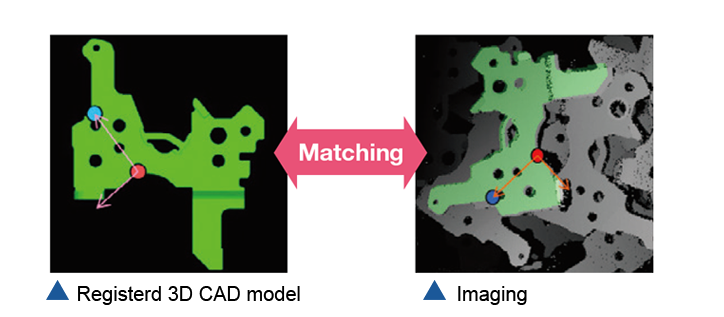

Model matching recognition

Model matching recognition is a method of picking up the workpiece by finding a workpiece that matches the registered 3D CAD model. This means that the grasp position and orientation of the workpiece can be specified.