FEATURES

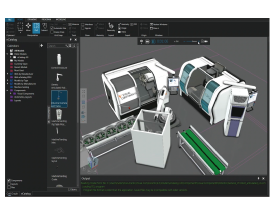

3D Simulator MELSOFT Gemini provides easier and more accurate simulation.

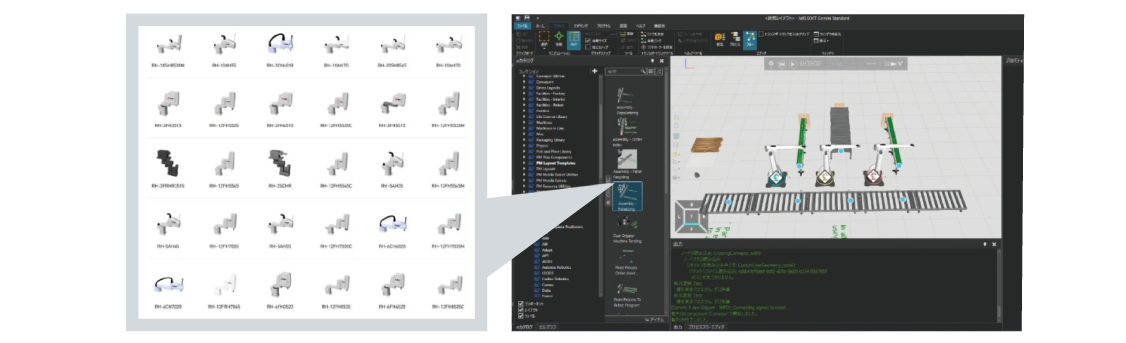

Contains all the parts necessary for line layout verification, including robots, conveyors, and machine tools (approx. 2800 parts).

Mitsubishi Electric robots are also included in the lineup, with emphasis on the MELFA RH and RV Series.

Layout is possible by dragging & dropping parts and performing simply settings.

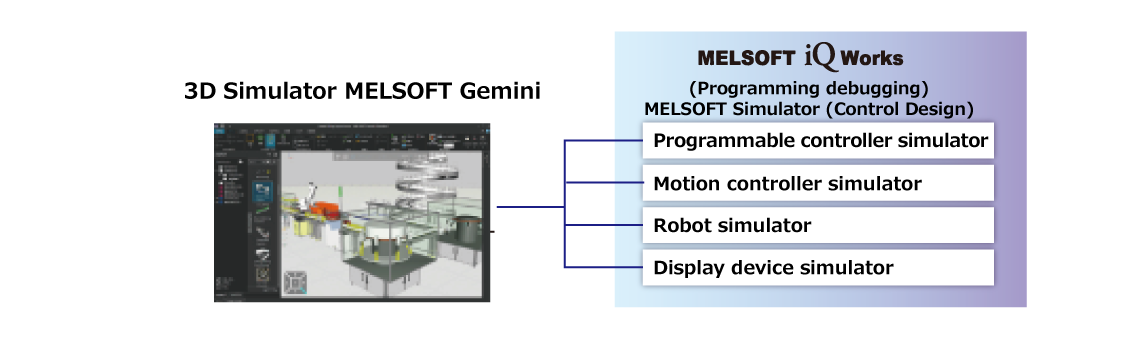

Control logic can be checked in 3D by synchronizing 3D Simulator and MELSOFT Simulator operations.

This enables pre-verification without a machine.

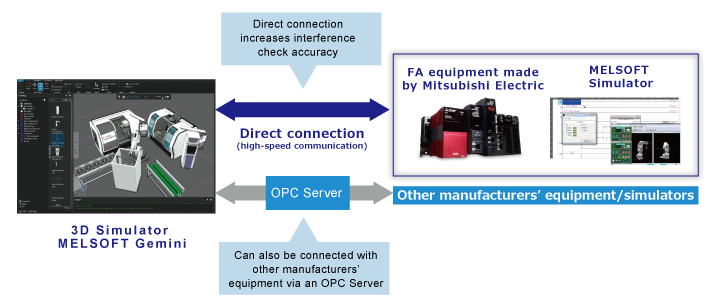

There is no longer a need for OPC servers because 3D Simulator can be directly connected to various simulators and FA equipment made by Mitsubishi Electric.

This means higher mechanical interference check accuracy compared to OPC connection.

Also reduces the labor hours required for setting due to no longer requiring OPC servers.

*Use OPC server when connecting with devices made by other companies

Able to compare operations using not only log data such as ladder monitor display and waveform display, and video display, but also 3D data.

Troubleshooting can be performed swiftly by checking the status in detail when a fault occurs.

Video recording

System recorder

- Log data

- Video data

Log data is displayed in a chart, enabling comparison of multiple data

A marking function swiftly reproduces video data at the time of error occurrence

Program status at time of error occurrence is reproduced based on log data

MELSOFT Gemini

3D model status at time of error occurrence is reproduced based on log data

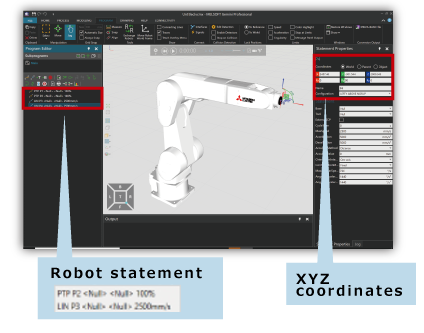

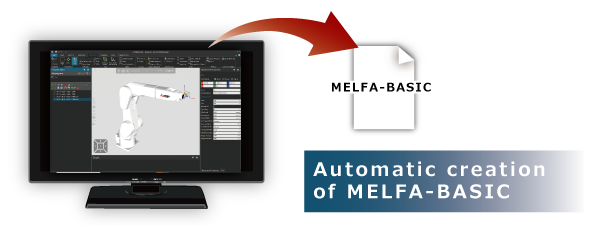

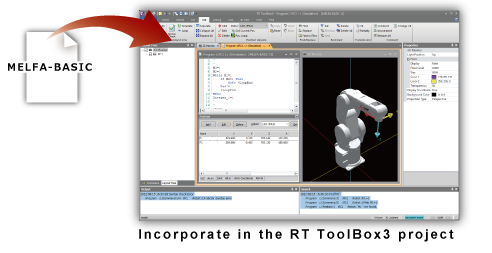

A MELFA-BASIC program is automatically generated based on a robot statement of a Mitsubishi Electric-made robot for which teaching has been conducted in MELSOFT Gemini.

Reduces time required to prepare control programs.

Offline teaching using UI operation

3D Simulator MELSOFT Gemini

3D Simulator MELSOFT Gemini

Export program in MELFA-BASIC format

3D Simulator MELSOFT Gemini

3D Simulator MELSOFT Gemini

Use file in RT ToolBox3

RT ToolBox3

RT ToolBox3

Other Features

1. Layout Configuration

- Compatible software types

- Professional

- Essentials

Swift layout is possible by dragging parts directly from the e-catalog to the settings screen and connecting components. By using the property editing function, it is possible to use pre-set component parameters such as dimensions, speed, and color.

2. Process Modeling

- Compatible software types

- Professional

- Essentials

With a visual workflow of part operation sequence, it is possible to perform settings where points are linked. Programming necessity can be set to the minimum with work content by line part/product flow or individual location.

3. CAD Import

- Compatible software types

- Professional

- Essentials

CAD files can be directly imported. 3D Simulator MELSOFT Gemini supports CAD file types of many major CAD vendors, therefore files created using common software applications such as Autodesk®, Dassault Systèmes, and PTC® can be easily imported.

4. File Generation in Various Formats

- Compatible software types

- Professional

- Essentials

It can output in a variety of formats for use in technical and marketing materials. Some examples of available formats are static images, 3D PDFs, and 2D drawings.

5. Graph/statistics feature

- Compatible software types

- Professional

- Essentials

Visualizes simulation statistics using line graphs, area charts, bar graphs, and pie charts. Bottlenecks can be identified and changes in operating ratio can be confirmed. If more detailed analysis is required, it is possible to easily export simulation data as PDF or Microsoft® Excel® files.

6. Component Modeling

- Compatible software types

- Professional

Mechanisms and operations can be set in the imported 3D CAD files. The motions of workpieces and equipment parts can be consistently reproduced in 3D Simulator.