What Is Factory Automation System

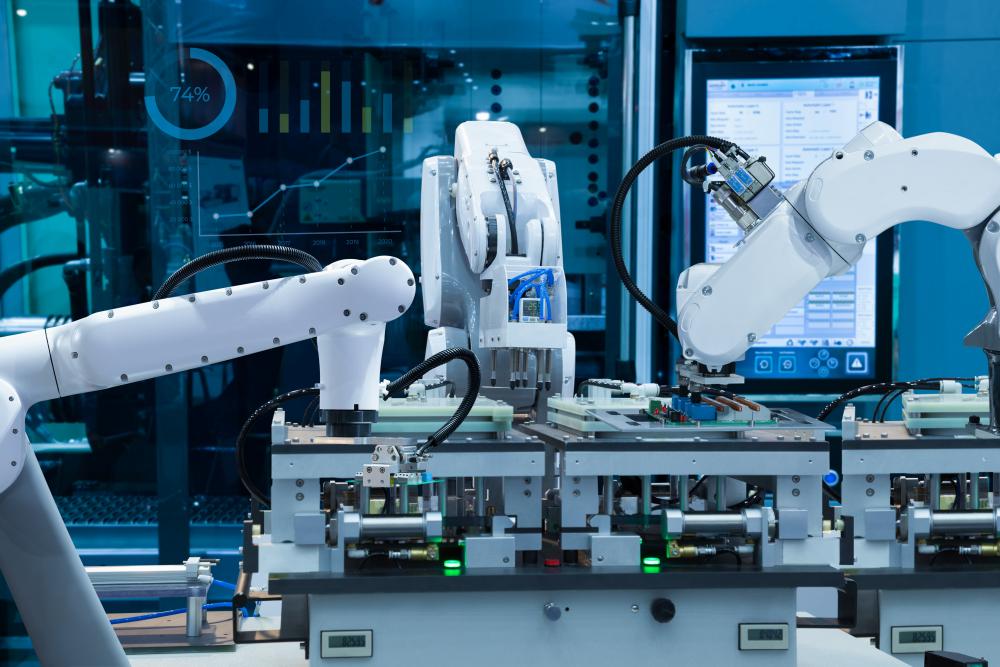

In recent years, factory automation systems have rapidly transformed the face of the manufacturing industry, akin to a small-scale “industrial revolution.” Businesses adopting this system have clearly outpaced their competitors. It’s no wonder many people are curious about what factory automation systems are, what they entail, and how they can enhance production efficiency. This article will take business owners on a deep dive into the world of factory automation in industrial settings, to understand the potential and challenges of the technology driving the future of manufacturing with efficiency.

What is Factory Automation?

Factory automation, or automated systems, refers to the use of technology to control and manage production processes in place of human labor. This involves machinery, robots, and software designed for specific tasks. In modern industries, factory automation plays a crucial role in controlling the production process from start to finish—from managing raw materials, production, and quality inspection, to packaging and shipping products.

Types of Factory Automation Systems

Fixed Automation

Fixed Automation is a highly efficient system designed for specific tasks. It is ideal for high-volume production that requires continuous operation, such as automotive production lines or food and beverage manufacturing plants. The advantages of this system include speed and accuracy, but its drawback is low flexibility. Changing production processes can be difficult and costly.

Programmable Automation

Next is Programmable Automation, a system where the operation program can be modified. It is suitable for production that involves a variety of products but still requires high production volumes. This system is often used in industries with batch production, such as electronics manufacturing or automotive parts production. The benefit is that the production process can be altered without changing the entire equipment setup, making it more flexible than Fixed Automation.

Flexible Automation

Flexible Automation is the most adaptable factory automation system, capable of rapidly changing tasks. It is suitable for factories that produce a variety of products and frequently change production details. This system is popular in industries with make-to-order production, such as fashion or specialized medical device manufacturing.

Integrated Automation

Finally, Integrated Automation combines several types of automated systems to create a comprehensive and highly efficient production system. This is typically found in large, complex factories, such as car manufacturing plants or large-scale electronics factories, where production systems, inventory management, and logistics systems are integrated.

Benefits of Using Factory Automation

- Increased Production Efficiency: Automated systems can operate continuously without breaks, significantly increasing production capacity.

- Faster Operations: Automated machines can work much faster than humans, especially for tasks requiring high precision and speed.

- Higher Output with Less Labor: Factory automation helps solve labor shortages and can reduce long-term personnel costs efficiently.

- Reduced Production Costs: Although the initial investment in automation systems can be high, in the long run, it can greatly reduce production costs by saving energy, reducing waste, and improving material utilization.

- Increased Workplace Safety: Automated systems can operate in environments that are hazardous to humans, reducing the risk of accidents among employees.

- Accurate Data Collection: Automation systems can collect detailed and precise production data, enabling more accurate analysis and improvement of production processes.

- Improved Product Quality: With precision and consistency in operations, automation systems help maintain high and stable product quality.

- Increased Competitiveness: Using advanced technology allows businesses to respond to market demands more quickly and efficiently.

Boost Your Business and Stay Ahead with Smart Factory Solutions from Mitsubishi FA

Now that business owners understand what factory automation is, what it entails, and how it can enhance production efficiency, if you want your industrial factory to compete in the digital age ahead of your competitors, with increased efficiency and reduced long-term costs, Mitsubishi FA offers smart factory solutions. These solutions not only connect all current systems but are also future-ready for rapid changes. Invest once, use long-term. For more details, feel free to contact us at sales@mitsubishifa.co.th or call 02 092 8600.

References

- Ways Automation Can (And Will) Impact The Manufacturing Industry. Accessed on July 16, 2024. From https://www.forbes.com/sites/forbestechcouncil/2024/03/28/ways-automation-can-and-will-impact-the-manufacturing-industry/