What Is Preventive Maintenance

Industrial manufacturing operators are well aware that one of the challenges of operating a 24/7 production line is the difficulty in maintaining and ensuring the efficiency of machinery. Continuous operation can lead to wear and tear, reduced performance, or even serious breakdowns that could halt production. Such stoppages result in higher costs.

Therefore, understanding preventive maintenance (PM), what it entails, and how essential it is to the production process, is crucial. If applied to a business, it can facilitate long-term sustainable production planning.

What is Preventive Maintenance (PM)?

Preventive Maintenance, or PM, is the process of regularly maintaining machinery, equipment, and systems in an industrial factory at scheduled intervals. The goal is to prevent unexpected breakdowns and ensure continuous operation. This process includes tracking machine status, inspections, cleaning, lubrication, and replacing worn-out parts within specified timeframes to keep the equipment functioning optimally.

The Importance of PM for Factory Equipment

- Reduces disruptions during production: Regular inspections can detect issues early, allowing timely repairs and preventing delays that could affect the supply chain.

- Extends equipment lifespan: Regular checks and maintenance ensure longer use of machinery by keeping parts in good condition.

- Boosts production efficiency: With smoothly running machinery, businesses can maximize production and reduce costs associated with replacing equipment due to poor maintenance.

- Reduces machinery costs: Preventive maintenance helps avoid major damages and costly repairs by addressing minor issues early. It also minimizes the need to replace irreparable machines.

- Lowers energy consumption: Poorly maintained machines typically consume more energy than those that receive regular PM. Addressing energy inefficiencies can lead to lower utility costs and increase profitability.

Types of Preventive Maintenance

Preventive Maintenance is a key strategy for maintaining industrial equipment and machinery. It can be categorized into three types, each with its specific benefits:

1. Time-Based Maintenance

This type schedules maintenance at fixed intervals, such as weekly, monthly, or yearly, regardless of the equipment's actual condition. Though it simplifies planning, it may not always align with actual equipment usage.

2. Predictive Maintenance

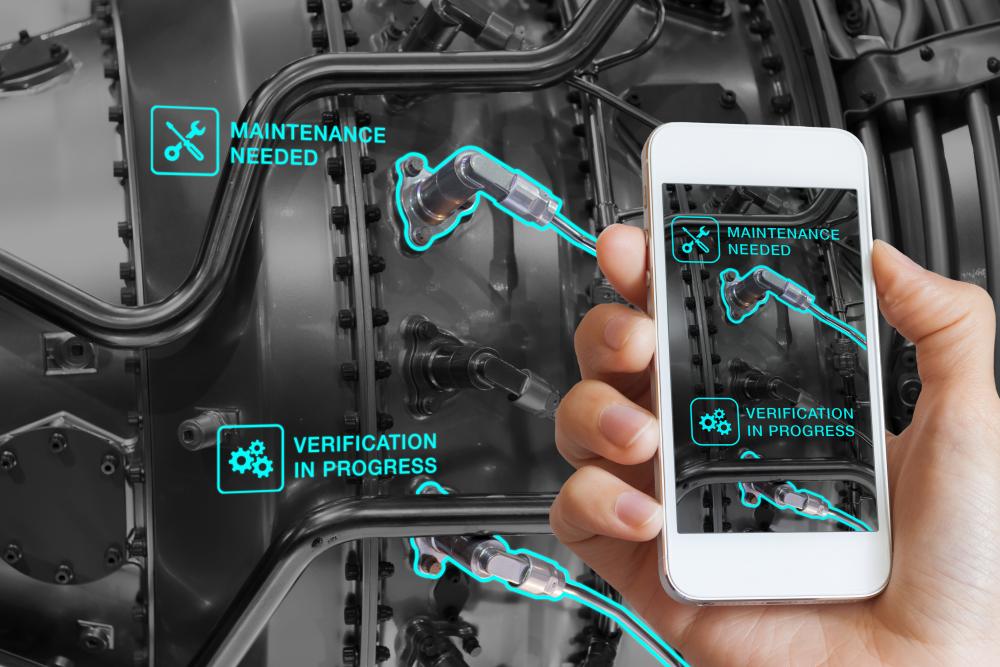

This method incorporates technology to analyze data and predict when equipment is likely to fail. Techniques like vibration analysis, temperature monitoring, and lubricant analysis allow for early intervention, reducing unnecessary downtime.

3. Prescriptive Maintenance

This is the most advanced form of maintenance, using artificial intelligence (AI) and machine learning to analyze vast amounts of data. It not only predicts when equipment may fail but also suggests the most effective actions to take for repairs.

Key Elements of PM for Machinery

The key elements in the PM process include clearly defined maintenance steps and scheduling that aligns with the type of machinery to achieve the best long-term results. This can help reduce machinery costs for the factory. There are five essential steps:

1. Regularly scheduled inspections

Scheduling regular inspections is at the heart of PM. Clear plans and schedules for daily, weekly, monthly, or yearly checks should be based on the type of equipment and its importance in production. Regular inspections allow for early detection of potential issues and prevent more severe damage.

2. Routine maintenance

Besides regular inspections, ongoing maintenance, including cleaning, lubrication, adjustments, and part replacements according to their service life, is crucial. This ensures that equipment operates efficiently and reduces the risk of unexpected breakdowns.

3. Prompt replacement of worn-out parts

After inspections, any worn or faulty parts should be replaced immediately. Waiting until they completely fail could lead to unplanned production halts and cause damage to other parts. Immediate replacement is key to maintaining equipment performance and preventing further issues.

4. Utilize predictive maintenance techniques

Combining PM with predictive maintenance techniques, such as sensors, data analysis, and AI, significantly enhances maintenance efficiency. This technology helps predict when equipment is likely to fail, allowing for more accurate maintenance planning, reduced downtime, and long-term cost savings.

5. Documentation and detailed records

The final step in the PM process is to document and record every maintenance activity. This includes keeping track of maintenance history, issues encountered, repairs made, and results. These records are essential for future analysis, training new staff, and knowledge-sharing within the organization.

Implementing these elements effectively can optimize the PM system, extending the lifespan of machinery and equipment. This ultimately benefits the management of industrial factories, allowing them to operate sustainably.

If your industrial factory seeks to enhance its preventive maintenance processes to ensure smooth and efficient operation, Mitsubishi FA offers automated system maintenance services with a team of experts. They provide tailored solutions and support from start to finish. For more details, contact sales@mitsubishifa.co.th or call 02 092 8600

References

- What is Preventive Maintenance, and why is it important in manufacturing? Retrieved July 17, 2024, from https://www.sumipol.com/knowledge/preventive-maintenance/

- Preventive Maintenance (PM). Retrieved July 17, 2024, from https://www.safesiri.com/preventive-maintenance/