Product Features

Vision sensors

Common functions for EasyBuilder/spreadsheet

Two development environments

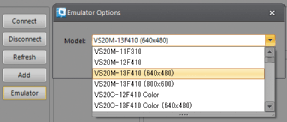

In-Sight Explorer includes two development environments "EasyBuilder" and "spreadsheet". Select suitable development environment according to the application to setup.

| Item | VS80 | VS70 | VS20 |

|---|---|---|---|

| EasyBuilder | |||

| Location tools | ● | ● | ●*1 |

| Presence/absence tools | ● | ● | ●*1 |

| Measurement tools | ● | ● | ●*1 |

| Counting tools | ● | ● | ●*1 |

| Identification tools | ● | ● | – |

| Geometry tools | ● | ● | – |

| Math & logic tools | ● | ● | – |

| Plot tools | ● | ● | – |

| Image filter tools | ● | ● | – |

| Defect detection tools | ● | ● | – |

| Calibration tools | ● | ● | – |

| Item | VS80 | VS70 | VS20 |

|---|---|---|---|

| Spreadsheet | |||

| Vision tools | ● | ● | – |

| Geometry | ● | ● | – |

| Graphics | ● | ● | – |

| Mathematics | ● | ● | – |

| Text | ● | ● | – |

| Coordinate transforms | ● | ● | – |

| Input/output | ● | ● | – |

| Clocked data storage | ● | ● | – |

| Vision data access | ● | ● | – |

| Structures | ● | ● | – |

| Scripting | ● | ● | – |

EasyBuilder

EasyBuilder

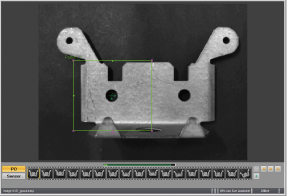

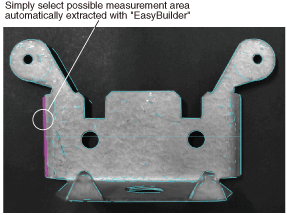

The ease-of-use In-Sight Explorer enables configuration from image acquisition to result output in four steps. Both novice and experienced users can handle the tool easily.

- Image acquisition

- Calibration setting

- Locate inspection target

- Inspection setting

- Communication protocol between programmable controller and robot

- Data collection setting

of GOT (HMI)

- Tool graphics

- Result table

- Film strip (image confirmation) setting

Connect to the vision sensor on the network.

Can easily use powerful vision tools.

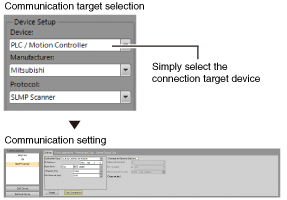

Select sending data by a point-and-click communications setup.

Useful for troubleshooting the image processing and identifying bad parts.

Spreadsheet

Spreadsheet

By flexibly arranging functions on the spreadsheet, jobs can be created. This spreadsheet is ideal for configuring complex applications.

Select a function from the function list on the right, then add it to the area to create a job. After adding functions, parameters can be entered on the property sheet.

Download

* Available for free download

Vision sensors

High-performance and robust PatMax RedLine®

High-performance and robust PatMax RedLine®

PatMax RedLine® technology can find object shapes even in images which are difficult to detect due to noise, low contrast and reflection. The vision sensor detects out-of-focus images due to distortion of an object and variation of thickness at high speed, reducing inspection time such as pattern matching, filtering, defect detection, and barcode reading.

Since PatMax RedLine® can calculate an accurate position adjusted value, a mechanism to align objects is no longer required, thereby contributing to cost reduction and downsizing of facility.

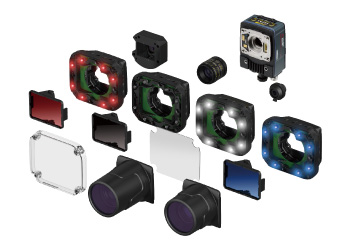

All necessary functions included

All necessary functions included

All necessary functions included

All necessary functions included

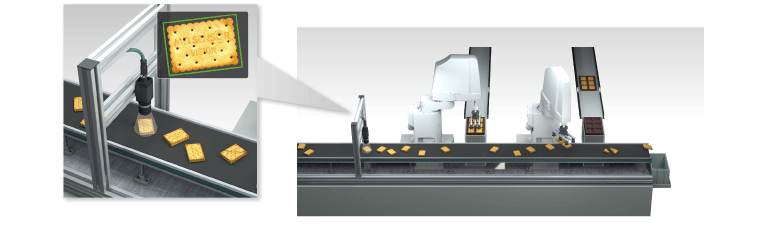

Mitsubishi Electric vision sensors are integrated vision sensors with all necessary functions embedded. Image acquisition, powerful vision tool library, and inspection result output function are available.

Support color verification

Support color verification

Support color verification

Support color verification

Integrated lighting and filter

Integrated lighting and filter

Integrated lighting and filter

Integrated lighting and filter

Extensive option products

Extensive option products

Extensive option products

Extensive option products

Lighting according to measured item characteristics

Lighting according to measured item characteristics

Lighting according to measured item characteristics

Lighting according to measured item characteristics

Lighting can be changed according to measured object and color.

| Color | Features | General applications |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

Field customizable to your applications

Field customizable to your applications

Field customizable to your applications

Field customizable to your applications

Vision sensor monitor function

Vision sensor monitor function

Specifications

Vision sensor monitor function

Vision sensor monitor function

| Item | Specifications |

|---|---|

| Number of detectable vision sensor (modules) | Max. 64 |

| Number of monitor/editable job files | Max. 100 |

| Editable parameters | Parameters for correcting inspection area and model area |

| Creating new job files | Not allowed*1 |

| Vertical display | Not allowed |

| Product | Series | Firmware version |

|---|---|---|

| Vision sensor | VS80, VS70, VS20 | Ver. 5.7.5 |

| GOT (HMI) | GOT2000 Series GT27, GT25 | Ver. 1.235V or later |