Programmable Controller

MELSEC iQ-R series

การควบคุมแบบบูรณาการและทรงประสิทธิภาพสำหรับทุกการใช้งาน

MELSEC iQ-R มีแพลตฟอร์มการควบคุมที่โดดเด่นเต็มรูปแบบพร้อมด้วยการประมวลผลที่รวดเร็ว การซิงโครไนซ์โมดูลและเครือข่าย รวมไปถึงการควบคุมแบบ multi-discipline การออกแบบขั้นสูงของ MELSEC iQ-R ช่วยพัฒนาประสิทธิภาพการผลิตและการทำงานของเครื่องได้อย่างยอดเยี่ยม และยังมีตัวเลือก CPU และ I / O จำนวนมาก สำหรับการใช้งานที่หลากหลาย

การควบคุมแบบบูรณาการและทรงประสิทธิภาพสำหรับทุกการใช้งาน

MELSEC iQ-R มีแพลตฟอร์มการควบคุมที่โดดเด่นเต็มรูปแบบพร้อมด้วยการประมวลผลที่รวดเร็ว การซิงโครไนซ์โมดูลและเครือข่าย รวมไปถึงการควบคุมแบบ multi-discipline การออกแบบขั้นสูงของ MELSEC iQ-R ช่วยพัฒนาประสิทธิภาพการผลิตและการทำงานของเครื่องได้อย่างยอดเยี่ยม และยังมีตัวเลือก CPU และ I / O จำนวนมาก สำหรับการใช้งานที่หลากหลาย

จุดเด่น

• ประมวลผลโดยใช้เวลาเพียง 0.98 ns ทำให้กระบวนการผลิตมีประสิทธิภาพมากขึ้น

• สามารถใส่โมดูลซีพียูได้ถึง 4 โมดูลในรางเดียว ช่วยให้การสื่อสารข้อมูลเป็นไปได้อย่างรวดเร็วและสมบูรณ์

• ปรับปรุงโปรแกรมและแก้ไขปัญหาได้ง่ายขึ้นด้วยโปรแกรม GX Works3

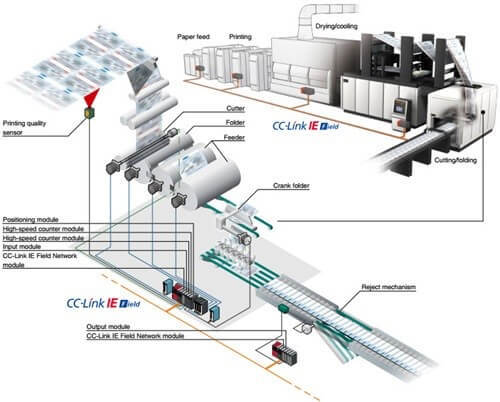

• เพิ่มความเร็วในการตอบสนองของเครื่องจักร และการสื่อสารข้อมูลได้ด้วยการใช้เครือข่าย CC-Link IE Field network ที่เป็นการเชื่อมต่อ Ethernet สำหรับอุตสาหกรรม

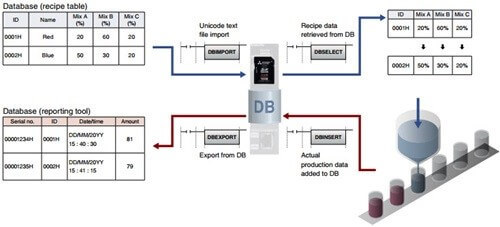

• สามารถใช้ฟังก์ชัน recipe และ data logging ได้ในตัว ด้วย Built-in SD memory card

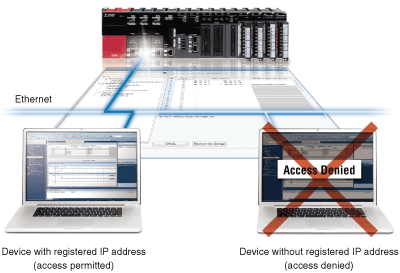

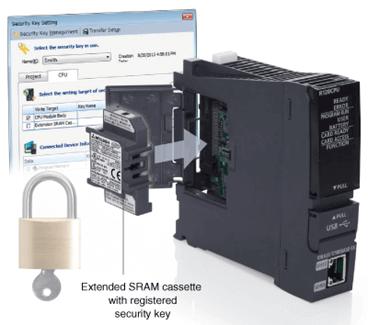

• ปลอดภัยยิ่งขึ้นด้วยฟีเจอร์ความปลอดภัย

CPU

ตัวควบคุมระบบอัตโนมัติแบบตั้งโปรแกรมได้ที่ใช้งานได้หลากหลาย

Base unit

สำหรับการติดตั้งอุปกรณ์ต่างๆ เช่น แหล่งจ่ายไฟ, CPU และโมดูลอินพุท/เอาท์พุท มีหน่วยฐานมากมายเพื่อให้เหมาะกับความต้องการของระบบต่างๆ

Power supply

โมดูลนี้ใช้สำหรับการจ่ายพลังงานไฟฟ้าสำหรับโมดูล CPU, อินพุท, เอาท์พุท และโมดูลอื่นๆ บนหน่วยฐาน

I/O module

อุปกรณ์ต่างๆ เช่น สวิตช์ ไฟแสดงสถานะ และเซ็นเซอร์สามารถเชื่อมต่อกับระบบควบคุมได้อย่างง่ายดายโดยใช้โมดูล I/O ดิจิตอล

Analog I/O module

โมดูลอะนาล็อกคือ อินเทอร์เฟซหลักระหว่างกระบวนการควบคุมและระบบอัตโนมัติ และออกแบบมาโดยเฉพาะสำหรับอินเทอร์เฟซที่มีเซ็นเซอร์ ซึ่งประมวลผลแรงดันไฟฟ้าและสัญญาณกระแสไฟฟ้าต่างๆ

Motion, Positioning, High-speed counter

ชุดต่างๆ ของโมดูลอัจฉริยะที่มีความแม่นยำสูงและตอบสนองการควบคุมรวดเร็วเหมาะสำหรับการใช้งานที่ต้องการความเร็วและความแม่นยำสูง

Information/network module

กลุ่มโมดูลนี้ทำให้สามารถแลกเปลี่ยนข้อมูลกับระบบควบคุมหลายระบบ กลุ่มโมดูลจะเพิ่มประสิทธิภาพการผลิตโดยการรวบรวมและควบคุมข้อมูลการผลิตต่างๆ

Recorder module

โมดูลที่ใช้ในการบันทึก log สำหรับบันทึกข้อมูลระบบซึ่งรวบรวมข้อมูลทั้งหมดต่อรอบการสแกนของตัวควบคุม ทั้งก่อนและหลังการเกิดข้อผิดพลาดพร้อมกับการบันทึกเวลาที่เกิด

|

ไลน์อัพ |

Programmable

controller CPU: 8 models |

|

วิธีการควบคุม |

Stored program

cyclic operation |

|

รูปแบบการควบคุมI/O |

Refresh mode |

|

ภาษาโปรแกรมที่รองรับ |

Ladder diagram |

|

โปรแกรมสำหรับการตั้งค่า |

MELSOFT GX Works3 |

|

ขนาดโปรแกรม(K step) |

1200 |

|

จำนวน I/O points [X/Y] (point) |

4096 |

|

Device/label memory/

standard RAM (K byte) |

3380 |

|

ข้อมูลหน่วยความจำ/ standard ROM (byte) |

40 M |

|

ความเร็วของการประมวลผล |

|

|

คำสั่ง LD (ns) |

0.98 |

|

คำสั่ง MOV (ns) |

1.96 |

|

การเพิ่ม Floating point (µs) |

0.01 |

|

หน่วยความจำ |

|

|

Extended SRAM

cassette |

● |

|

SD memory card |

● |

|

SRAM card, FLASH

card, ATA card |

— |

|

พอร์ตการเชื่อมต่อ |

|

|

USB |

● |

|

Ethernet |

● |

|

RS-232 |

— |

|

RS-422/485 |

— |

|

Display unit |

— |

|

พอร์ตการเชื่อมต่อ CC-Link IE |

|

|

Ethernet |

●*12 |

|

การเชื่อมต่อเครือข่าย (adapter/module) |

|

|

Ethernet |

● |

|

CC-Link IE Control |

● |

|

CC-Link IE Field |

● |

|

CC-Link |

● |

|

CC-Link/LT |

— |

|

SSCNET Ⅲ/H |

● |

|

AnyWire |

● |

|

BACnet™ |

● |

|

MODBUS®/TCP |

● |

|

MODBUS® |

● |

|

ข้อกำหนดเบื้องต้น/มาตรฐานที่รองรับ |

|

|

Operating ambient

temperature |

0...55℃ (60℃*17) |

|

International safety

standards |

●*18 |

|

Standard on

corrosive atmosphere |

●*19 |

|

CE: Council

Directive of the European Communities |

● |

|

UL: Underwriters

Laboratories Listing |

● |

|

LR: Lloyd's Register

of Shipping approval |

● |

|

DNV: Norwegian

Maritime approval |

● |

|

RINA: Italian

Maritime approval |

● |

|

NK: ClassNK approval |

● |

|

ABS: American Bureau

of Shipping approval |

● |

|

BV: Bureau Veritas

approval |

● |

|

GL: Germanischer

Lloyd approval |

● |

|

จุดเด่น/ฟังก์ชันการทำงาน |

Line manufacturing |

*1: Supports redundant

system when paired with R6RFM

*2: SFC is not supported in redundant mode and

by safety CPU

*3: Q□UDVCPU only

*4: When using CW Workbench

*5: Does not support QnUDVCPU and certain models

*6: Does not support L02SCPU(-P)

*7: Supports the user Ethernet port of

Q24DHCCPU-V/VG/LS and Q26DHCCPU-LS only

*8: Supports Q□UDE(H)CPU and Q□UDVCPU only

*9: Does not support Q□UDE(H)CPU and Q□UDVCPU

*10: Supports L02SCPU(-P) only

*11: Supports FX3G only

*12: R□ENCPU only

*13: Supports the MELSEC iQ-R Series only.

*14: Supported by expansion board

*15: Does not support Q□(P)(H)CPU and Q□PRHCPU

*16: Supports SSCNET Ⅲ

*17: Only supported when used together with

extended temperature range main/extension base units

*18: R□SFCPU-SET only.

*19: For protection against aggressive

atmosphere and gases, products with a conformal coating (JIS C 60721-3-3/IEC

60721-3-3 Class 3C2) are available on request

*20: Operating ambient temperature from -20℃ is supported by products produced from June

2016 (serial number "166" or later). For details, on supported

products, please refer to the relevant product manual.

ตารางเปรียบเทียบผลิตภัณฑ์

รุ่น | แบบ Modular | แบบ Modular | แบบ Baseless |

|

|

| |

PAC (Programmable automation controller) | Programmable controller CPU | Programmable controller CPU | |

ไลน์อัพ | Programmable controller CPU: 8 models | Programmable controller CPU (Universal model): 25 models | Programmable controller CPU |

วิธีการควบคุม | Stored program cyclic operation | Stored program cyclic operation | Stored program cyclic operation |

รูปแบบการควบคุมI/O | Refresh mode | Refresh mode | Refresh mode |

ภาษาโปรแกรมที่รองรับ | Ladder diagram | Ladder diagram | Ladder diagram |

โปรแกรมสำหรับการตั้งค่า | MELSOFT GX Works3 | MELSOFT GX Works2 | MELSOFT GX Works2 |

ขนาดโปรแกรม(K step) | 1200 | 1000 | 260 |

จำนวน I/O points [X/Y] (point) | 4096 | 4096 | 4096 |

Device/label memory/ standard RAM (K byte) | 3380 | 1792 | 768 |

ข้อมูลหน่วยความจำ/ standard ROM (byte) | 40 M | 16 M | 2 M |

ความเร็วของการประมวลผล | |||

คำสั่ง LD (ns) | 0.98 | 1.9 | 9.5 |

คำสั่ง MOV (ns) | 1.96 | 3.9 | 19 |

การเพิ่ม Floating point (µs) | 0.01 | 0.014 | 0.057 |

หน่วยความจำ | |||

Extended SRAM cassette | ● | ●*3 | — |

SD memory card | ● | ●*3 | ●*6 |

SRAM card, FLASH card, ATA card | — | ●*5 | — |

พอร์ตการเชื่อมต่อ | |||

USB | ● | ● | ● |

Ethernet | ● | ●*8 | ●*6 |

RS-232 | — | ●*9 | ●*10 |

RS-422/485 | — | — | — |

Display unit | — | — | ● |

พอร์ตการเชื่อมต่อ CC-Link IE | |||

Ethernet | ●*12 | — | — |

การเชื่อมต่อเครือข่าย (adapter/module) | |||

Ethernet | ● | ● | ● |

CC-Link IE Control | ● | ● | — |

CC-Link IE Field | ● | ●*15 | ● |

CC-Link | ● | ● | ● |

CC-Link/LT | — | ● | ● |

SSCNET Ⅲ/H | ● | ● | ● |

AnyWire | ● | ● | ● |

BACnet™ | ● | ● | ● |

MODBUS®/TCP | ● | ● | ● |

MODBUS® | ● | ● | ● |

ข้อกำหนดเบื้องต้น/มาตรฐานที่รองรับ | |||

Operating ambient temperature | 0...55℃ (60℃*17) | 0...55℃ | 0...55℃ |

International safety standards | ●*18 | — | — |

Standard on corrosive atmosphere | ●*19 | — | — |

CE: Council Directive of the European Communities | ● | ● | ● |

UL: Underwriters Laboratories Listing | ● | ● | ● |

LR: Lloyd's Register of Shipping approval | ● | ● | — |

DNV: Norwegian Maritime approval | ● | ● | — |

RINA: Italian Maritime approval | ● | ● | — |

NK: ClassNK approval | ● | ● | — |

ABS: American Bureau of Shipping approval | ● | ● | — |

BV: Bureau Veritas approval | ● | ● | — |

GL: Germanischer Lloyd approval | ● | ● | — |

จุดเด่น/ฟังก์ชันการทำงาน | Line manufacturing | Line manufacturing | Machine control |

*1: Supports redundant system when paired with R6RFM

*2: SFC is not supported in redundant mode and by safety CPU

*3: Q□UDVCPU only

*4: When using CW Workbench

*5: Does not support QnUDVCPU and certain models

*6: Does not support L02SCPU(-P)

*7: Supports the user Ethernet port of Q24DHCCPU-V/VG/LS and Q26DHCCPU-LS only

*8: Supports Q□UDE(H)CPU and Q□UDVCPU only

*9: Does not support Q□UDE(H)CPU and Q□UDVCPU

*10: Supports L02SCPU(-P) only

*11: Supports FX3G only

*12: R□ENCPU only

*13: Supports the MELSEC iQ-R Series only.

*14: Supported by expansion board

*15: Does not support Q□(P)(H)CPU and Q□PRHCPU

*16: Supports SSCNET Ⅲ

*17: Only supported when used together with extended temperature range main/extension base units

*18: R□SFCPU-SET only.

*19: For protection against aggressive atmosphere and gases, products with a conformal coating (JIS C 60721-3-3/IEC 60721-3-3 Class 3C2) are available on request

*20: Operating ambient temperature from -20℃ is supported by products produced from June 2016 (serial number "166" or later). For details, on supported products, please refer to the relevant product manual.