Motion Controllers

EMBEDDED TYPE SERVO SYSTEM CONTROLLER

การควบคุมเซอร์โวเฉพาะที่สามารถทำได้ผ่านการเขียนโปรแกรมภาษา C

การควบคุมเซอร์โวที่มีการตอบสนองสูงสามารถใช้ร่วมกับตัวควบคุม C และโมดูลอินเทอร์เฟซ หรือคอมพิวเตอร์ส่วนบุคคลและบอร์ดตำแหน่ง

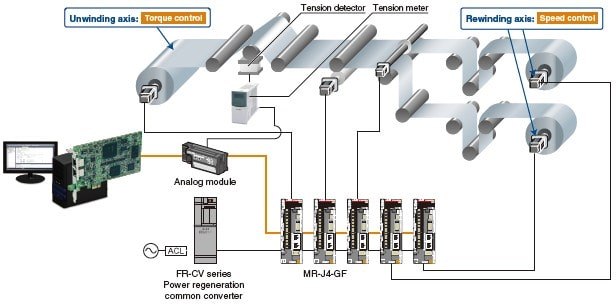

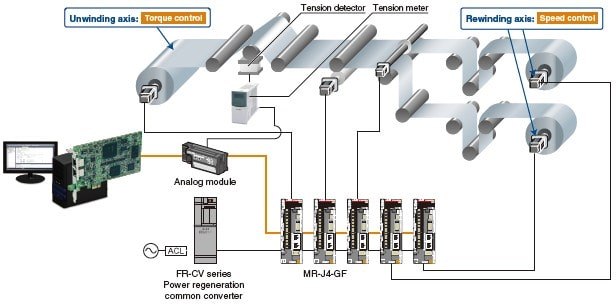

Speed-Torque Control

Speed

control follows speed commands to keep the speed constant, and torque control

follows torque commands to keep the torque constant.

The Simple Motion board can be used for the speed-torque control, such as

unwinding or rewinding.

Positioning using absolute position coordinates can be smoothly performed even

after switching back to position control because the current position is

controlled during the speed-torque control.

The Simple Motion board can be used for the speed-torque control, such as unwinding or rewinding.

Positioning using absolute position coordinates can be smoothly performed even after switching back to position control because the current position is controlled during the speed-torque control.

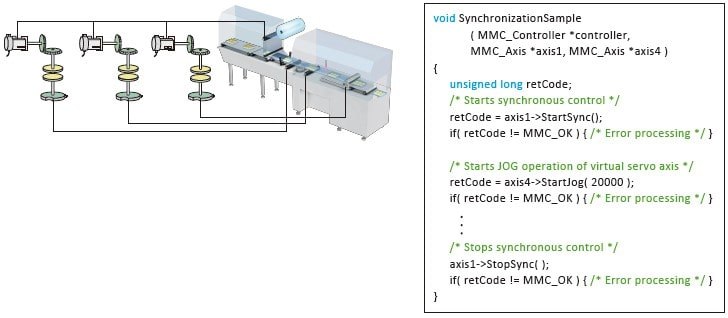

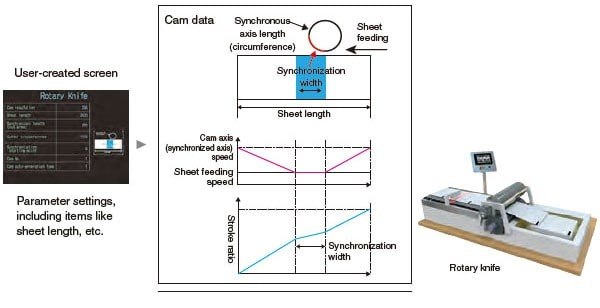

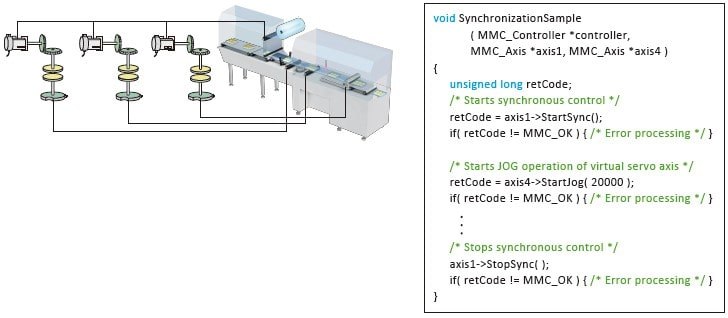

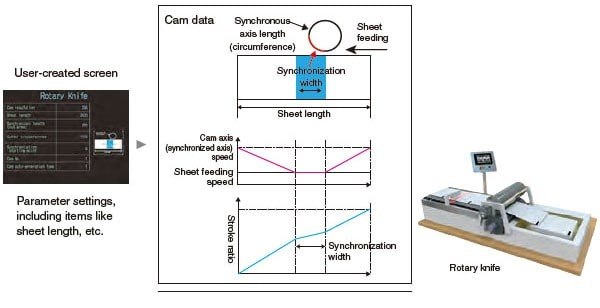

Advanced Synchronous Control

The advanced synchronous control

is software-based synchronous control as an alternative to mechanical control,

such as gear, shaft, clutch, speed change gear, and cam. In addition, a cam is

easily generated with cam auto-generation function. The synchronous control can

be started and ended for each axis, allowing the synchronous control axis and

positioning control axis within the same program.

Cam auto-generation

Cam data for a rotary cutter can

be generated automatically simply by parameter settings of sheet length,

synchronization width, cam resolution, etc.

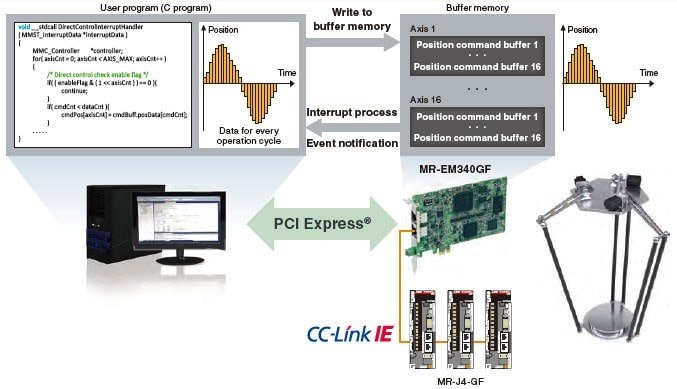

Direct

control

The direct control is a function

that controls servo amplifiers directly by transmitting set command positions

for each operation cycle from a user program to the servo amplifiers.

·

The direct control can be combined with positioning control.

·

Control can be switched between the direct control and the

positioning control.

·

A personal computer with a real-time operating system can

perform fixed-cycle Motion control using interrupts at every operation cycle.

· Thanks to the position command buffers of up to 16 phases, even non-real-time operating system (Windows® ) can perform at 0.5 ms (the fastest rate) cycle command operation; This enables further increase in accuracy in trajectory control.

(Note): Execute coordinate conversion of a parallel link robot with a user program.

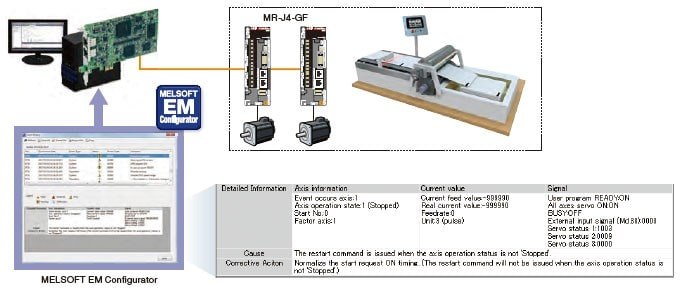

Event history

Events occurred on each slave device and servo amplifiers can be stored to the Simple Motion board. Information of "WRITE" operation to the program, error occurrence, etc. is listed chronologically, enabling an investigation of the cause of the error and a prompt restoration of servo amplifiers.

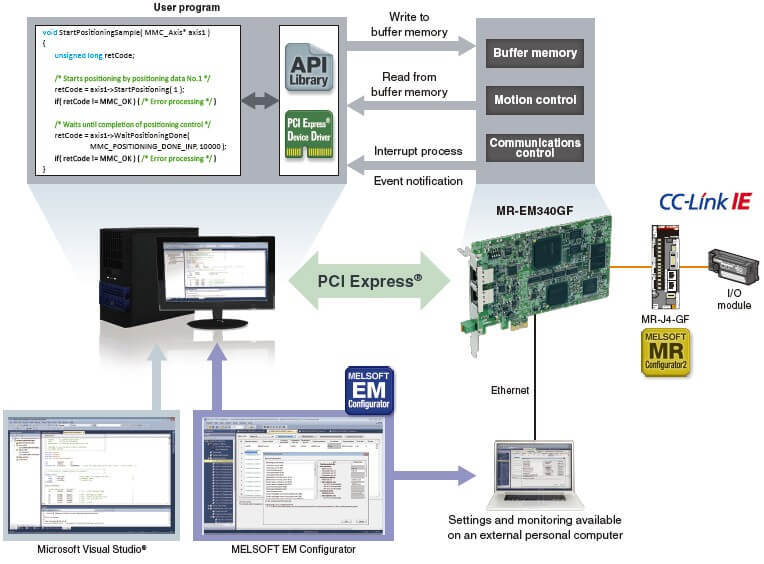

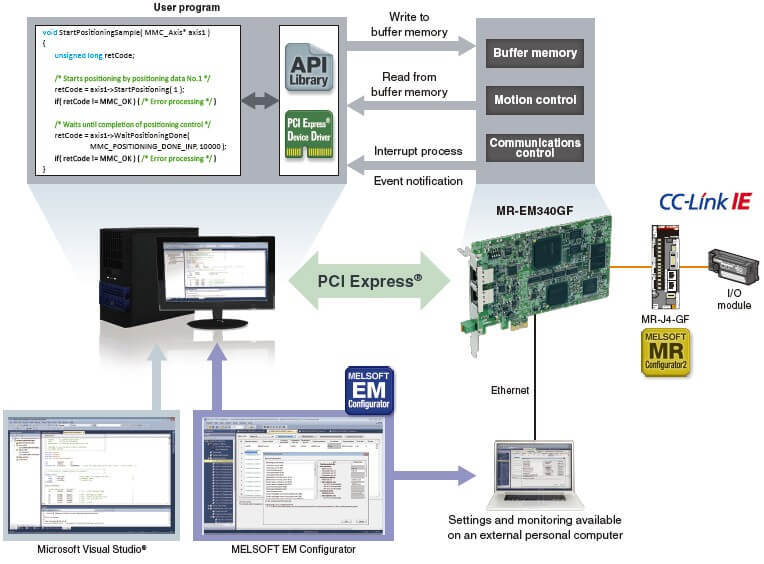

Software Development Kit MELSOFT EM Software Development Kit

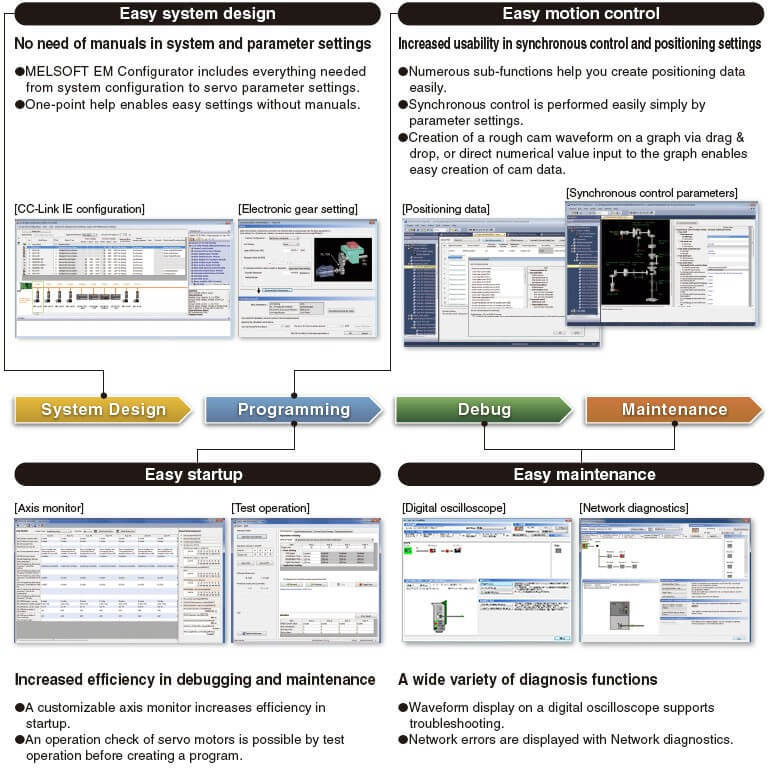

MELSOFT EM Software Development Kit is a development software package, supporting the engineering process from system design and programming to debug and maintenance for the Simple Motion board.

MELSOFT EM Configurator - Every step in the engineering process from system design

and programming to debug and maintenance, is supported by this software.

MELSOFT EM Configurator - Every step in the engineering process from system design

and programming to debug and maintenance, is supported by this software.

MELSOFT MR Configurator2 - Primarily, tuning, monitoring, and diagnosis are easily

performed with this software by being connected to a servo amplifier.

MELSOFT MR Configurator2 - Primarily, tuning, monitoring, and diagnosis are easily

performed with this software by being connected to a servo amplifier.

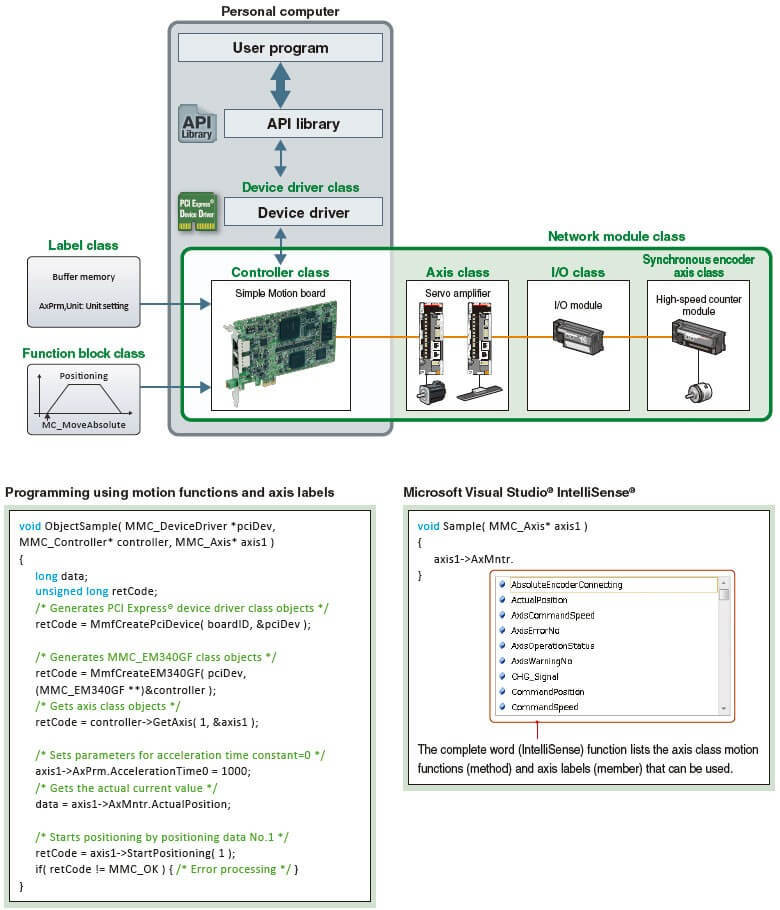

API library - The API library is an add-on library which uses functions

(method) and labels (member) of controller and axis classes, and enables easy

programming with Visual C++®.

API library - The API library is an add-on library which uses functions

(method) and labels (member) of controller and axis classes, and enables easy

programming with Visual C++®.

PCI Express® device driver - The PCI

Express® device driver is software for a user program to gain

access to the Simple Motion board via PCI Express®.

PCI Express® device driver - The PCI

Express® device driver is software for a user program to gain

access to the Simple Motion board via PCI Express®.

(Note): Contact

your local sales office for the latest version of Software Development Kit.

Development and Debugging Environments

A user

program is created by adding the API library (for motion control) to a project

of Microsoft Visual Studio®.

● INtime® and RTX (real-time operating system) are supported.

(Note):

Contact your local Mitsubishi Electric office for more details.

(Note): OS and the development environment are not included.

● INtime® and RTX (real-time operating system) are supported.

MELSOFT EM

Configurator (Setting Tool for Simple Motion Board)

MELSOFT EM

Configurator (Setting Tool for Simple Motion Board)

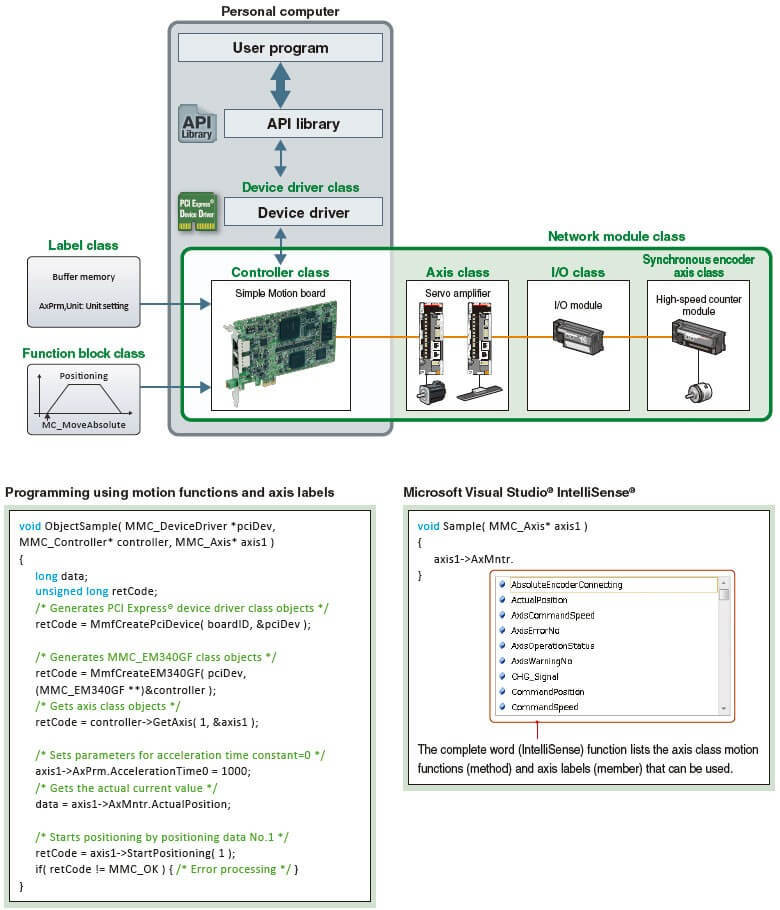

API library (C++

motion class library)

API library (C++

motion class library)

With the C++ motion class

library, a program is created using functions (method) and labels (member) of

controller and axis classes, and other classes.

·

The class library creates the program with high readability.

·

Coding time is reduced with Microsoft Visual Studio® IntelliSense®.

·

Compatibility with event-driven programming is improved by

specifying any bit data as a condition of interruption.

·

The library with the same interface specifications as PLCopen® Motion

Control FB, is available and suitable for fixed-cycle programming.

[Conception

diagram of class types in C++ motion class library]

CC-Link IE Field Network Servo Amplifier MR-J4-GF

CC-Link IE Field Network servo

amplifiers achieve an optimal solution and improve productivity in combination

with the Simple Motion board.

·

Industry-leading basic performance

Industry-leading levels of servo amplifier basic performance shorten a machine

cycle time.

·

Advanced servo gain adjustment

The advanced vibration suppression control function is easily used for

maximizing your machine performance.

·

A wide range of product series and capacities

From rotary to linear and direct drive motors, a wide range of servo motors are

available, significantly improving your machine performance.

·

Preventive maintenance

The data inside a servo amplifier are read via the network, and used for

preventive maintenance, such as machine diagnostics.

Industry-leading levels of servo amplifier basic performance shorten a machine cycle time.

The advanced vibration suppression control function is easily used for maximizing your machine performance.

From rotary to linear and direct drive motors, a wide range of servo motors are available, significantly improving your machine performance.

The data inside a servo amplifier are read via the network, and used for preventive maintenance, such as machine diagnostics.

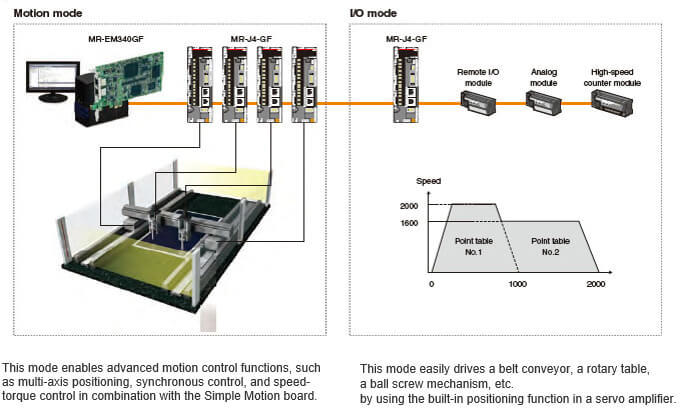

Control mode

Two types of modes are available

according to your needs:

·

Motion mode for a wide range of motion control functions, such

as multiple-axis positioning, synchronous control, etc.

·

I/O mode for single-axis positioning

C Controller Interface module

โมดูลอินเทอร์เฟซของตัวควบคุม C จะกำหนดค่าระบบเซอร์โวที่มีการตอบสนองสูงร่วมกับตัวควบคุม C

Position board

ฝังใน PC บอร์ดตำแหน่งจะกำหนดค่าระบบเซอร์โวที่มีการตอบสนองสูง

Functions List

| Simple Motion board | ||||

|---|---|---|---|---|

| MR-EM340GF | ||||

| Maximum number of control axes (virtual servo amplifier axis included) | 16 axes | |||

| Servo amplifier connection system | CC-Link IE Field Network | |||

| Maximum distance between stations [m(ft.)] | 100(328.08) | |||

| Connectable servo amplifier | MR-J4-GF , MR-J4-GF-RJ | |||

| Operation cycle (operation cycle settings) | 0.5 ms, 1.0 ms, 2.0 ms, 4.0 ms | |||

| Engineering Environment | MELSOFT EM Software Development Kit | |||

| Control modes | Positioning, Trajectory control (linear, arc, and helical), Speed control, Speed-torque control | |||

| Control unit | mm, inch, degree, pulse | |||

| Number of positioning data | 600 data/axis | |||

| Acceleration/deceleration process | Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration | |||

| Manual control | JOG operation, Manual pulse generator, Inching operation | |||

| Expansion control | Direct control | |||

| Functions that change control details | Current value change, Target position change function, Torque change function, Speed change function, Override function, Acceleration/deceleration time change function | |||

| Home position return method | Driver home position return method | |||

| Auxiliary functions | Forced stop function, Hardware stroke limit function, Software stroke limit function, Absolute position system, Amplifier-less operation function, Unlimited length feed, Optional data monitor function, Mark detection function, Flash ROM backup, M-code output function, Event history function, Digital oscilloscope function, Cam auto-generation function | |||

| Number of occupied I/O points | 32 points (I/O allocation: Intelligent function module, 32 points) | |||

| Current consumption [A] | 12 VDC | 0.4 | ||

| 3.3 VDC | 0.6 | |||

| Mass [kg] | 0.13 | |||

Performance specifications of CC-Link IE Field Network

| Simple Motion module | |||

|---|---|---|---|

| MR-EM340GF | |||

| Maximum link points per network | RX | 16k points (16384 points, 2 kbytes) | |

| RY | 16k points (16384 points, 2 kbytes) | ||

| RWr | 8k points (8192 points, 16 kbytes) | ||

| RWw | 8k points (8192 points, 16 kbytes) | ||

| Maximum link points per station | Master station | RX | 16k points (16384 points, 2 kbytes) |

| RY | 16k points (16384 points, 2 kbytes) | ||

| RWr | 8k points (8192 points, 16 kbytes) | ||

| RWw | 8k points (8192 points, 16 kbytes) | ||

| Local station | RX | 2k points (2048 points, 256 bytes) | |

| RY | 2k points (2048 points, 256 bytes) | ||

| RWr | 256 points, 512 bytes | ||

| RWw | 256 points, 512 bytes | ||

| Intelligent device station | RX | 2k points (2048 points, 256 bytes | |

| RY | 2k points (2048 points, 256 bytes | ||

| RWr | 256 points, 512 bytes | ||

| RWw | 256 points, 512 bytes | ||

| Remote device station | RX | 128 points, 16 bytes | |

| RY | 128 points, 16 bytes | ||

| RWr | 64 points, 128 bytes | ||

| RWw | 64 points, 128 bytes | ||

| Ethernet | Communication speed | 1Gbps | |

| Connection cable | 1000BASE-T Ethernet cable (Note-1): category 5e or higher (double shielded/STP) straight cable | ||

| Maximum distance between stations [m(ft.)] | 100(328.08) (conforms to ANSI/TIA/EIA-568-B (category 5e)) | ||

| Topology | Line type, star type, line/star mixed type | ||

| Overall cable distance | Line type [m(ft.)] | 12000(39370.08) (When 1 master station and 120 slave stations are connected) | |

| Star type(Note-2) | Depends on system configuration | ||

| Maximum connectable stations per network | 121 stations (1 master station. 120 slave stations) | ||

| Maximum number of networks | 239 | ||

(Note-1): Use the cables recommended by CC-Link Partner Association for CC-Link IE Field Network.

CC-Link IE Controller Network cables are not compatible with CC-Link IE Field Network.

(Note-2): A switching hub is required for star topology.