Servo

MELSERVO-JN SERIES

ใช้งานง่าย ประสิทธิภาพสูง และมีขนาดกะทัดรัด

MR-JN มีฟังก์ชั่นการทำงานพื้นฐาน

เช่น การปรับแต่งด้วยสัมผัสเดียว การกำหนดตำแหน่งในตัวที่มีตารางชี้

และการตั้งโปรแกรม

Pursuing of "EASY" for both Operation and Support

Fuss-free Quick tuning with one-touch

Various adjustments for bringing out the full-performance of the servo, such as estimation of load to motor inertia moment ratio, gain adjustment or machine resonance suppression, can be executed automatically with one-touch operation. (Patent pending)

|  |

Besides 1-phase 200VAC servo amplifier, 1-phase 100VAC servo amplifier is available.

* 100VAC servo amplifier is available in 200W or smaller.

Easy power supply wiring without a screwdriver

Easy setting of electronic gear

Calculation of command pulse frequency and travel distance of the ball screw is simple since the number of command pulses per revolution of motor is set to 10000 by default. Additionally, rotation angle is controlled easily just by setting one parameter.

Setting Examples  (10mm per 10000 pulses) .

| In the case of the number of command pulses per revolution is set to 36000:

The servo motor rotates 0.01 degrees per pulse.(1 degree per 100 pulses)

|

Support your inctallation totally

Freeware for capacity calculation

Freeware for capacity calculation

Capacity selection software (MRZJW3-MOTSZ111E) enables optimal selections of servo motor and servo amplifier for your system. This software is available for free download. Contact your local sales office for more details.

Reliable operation with "tough drive function" *1

● Overload tough drive function By using the overload tough drive function, machine operation is adjusted automatically to prevent an alarm occurrence when load changes in the machine are detected, and thereby reduces time losses caused by machine stops. (Patent pending)  | ● Instantaneous power failure tough drive function When an instantaneous power failure is detected, power charged on the main circuit capacitor is supplied to keep the system running. * Low voltage alarm may occur depending on the load conditions.  |

This function readjusts the machine resonance suppression filter automatically and prevents resonance when a machine resonance frequency is changed due to aging distortion. Vibration tough drive function

*1 Tough drive function is activated by setting a parameter.

Safe maintenance due to separated power supply for main and control circuits

Because each of the main circuit power supply (1-phase 200VAC or 1-phase 100VAC) and the control circuit power supply (24VDC) has the respective connectors, the main circuit power supply can be turned off separately. It makes the maintenance such as parameter setting or checking of machine status safer when a trouble occurs.

"Reduced Setting Space" Makes Your Manufacturing Floor

More Comfortable

High performance with small body! Even high-accuracy positioning can be done easily!!

● The servo motor is equipped with high-resolution encoder (131072p/rev), enabling both high-accuracy positioning and speed stability in low speed. The servo amplifier supports 1 Mpps command pulse frequency, realizing high-accuracy positioning. MELSERVO-JN can be used for various applications.

● MR-C series servo amplifier can be replaced easily by the MR-JN since both of these servo amplifiers have the same mounting dimensions.

The servo amplifier can be installed closely with each other.

The MR-JN servo amplifiers can be installed

closely with each other.

* The operation environment differs when

mounted closely. For details, refer to "Servo Amplifier

Specifications" and "Cautions concerning use" in the catalog.

Equipped with built-in regenerative resistor

200W or larger servo amplifier has a built-in

regenerative resistor. This space-saving servo amplifier contributes to smaller

system configurations.

Large Selection of Servo Motors

Compact high-performance servo motor HF-KN series

● Capacity: 50W to 400W

● By mounting the high-resolution

incremental encoder (131072p/rev), both "high-accuracy positioning"

and "speed stability in low speed" are enabled.

● Servo motors with electromagnetic brake

are also available.

● Cables can be led out either in

direction or in opposite direction of the motor shaft according to the selected

cables.

● The HF-KN series servo motor is rated

IP65 as standard. (excluding the shaft-through portion)

Geared servo motors, HF-KP series, are also available

● Capacity: 50W to 400W

● ● HF-KP series with reducer are available.

G1: for general industrial machines

G5: flange output type reducer for precision applications

G7: shaft output type reducer for precision applications

These servo motors are flange mounting type.

● Servo motors with electromagnetic brake

are also available.

● The HF-KP series with reducer is rated IP44 as standard. (excluding the shaft-through portion)

Equipped with MR-J3-level High Functionality

Extended adjustment functions by the auto tuning

● Advanced

vibration suppression control

The residual vibration with low frequency (up

to 100Hz) is suppressed automatically.

* An optimal filter is set automatically by the auto tuning function.

● Adaptive filter

II

High frequency machine resonance can be suppressed automatically by the one-touch tuning. Furthermore, by using the vibration tough drive function, the filter is readjusted automatically when a machine resonance is detected even after the tuning.

Various control modes

● Speed/torque

control operation

The speed control mode and the torque control mode are supported. (The speed

and the torque commands are set internally by parameters.)

● Torque limit

The torque generated by the servo motor can be controlled by setting

parameters.

Setup software "MR Configurator"

MR Configurator

enables high-speed sampling and long-time waveform measurement.

It makes start up and adjustments of the servo system easier.

A personal computer can be connected to the servo amplifier via USB.

Conformity with Global Standards

Complied with EN, UL and CSA standards

MELSERVO-JN conforms to the global standards.

*1 This product is not

a subject of China Compulsory Certification (CCC).

*2 HF-KN servo motor series will be compatible with EN, UL and CSA standards.

Complied with Restriction of Hazardous Substances Directive

(RoHS)

MELSERVO-JN is human and environmental-friendly AC servo compliant with RoHS directive. Additionally, our optional cables and connectors comply with "Measures for Administration of the Pollution Control of Electronic Information Products" (Chinese RoHS).

About RoHS

Directive

RoHS Directive requires member nations to guarantee that new electrical and

electronic equipment sold in the market after July 1, 2006 do not contain lead,

cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and

polybrominated diphenyl ether (PBDE) flame retardants.

Built-in positioning function (Note 1)

Positioning without a controller

A simple positioning system can be configured without a controller since the positioning function (point table and program methods) is built into the servo amplifier, saving cost and space.

Point table method

Setting position data

(target position), servo motor speed, and acceleration and deceleration time

constants in the point table is as easy as setting parameters.

Up to seven points are available for positioning. Positioning operation is

performed after selecting the point table number with an external interface

signal.

Program method (Note 2)

Simple positioning program can be created using dedicated commands. A program is executed with a start signal after selecting the program number with an external interface signal. Program method enables more complex positioning operation than point table method. Up to eight programs can be stored in the memory.

Notes:1. Servo

amplifier with software version BO or above is required for the positioning

function.

2. MR Configurator is required to create a program. MR Configurator with software version C4 or above is compatible with creating a program.

Servo Amplifier

มีอินเทอร์เฟซที่ใช้งานทั่วไป (อินพุทอะนาล็อกและพัลส์) และการกำหนดตำแหน่งในตัวที่มีการปรับแต่งด้วยสัมผัสเดียว, ฟังก์ชั่นการขับเคลื่อนที่มีความทนทาน

มอเตอร์เซอร์โว

Encoder ความละเอียด 131,072 พัลส์/รอบ, ใช้กับไฟ 100/200VAC และช่วงผลิตภัณฑ์ตั้งแต่ 50W จนถึง 400W

ซีรีส์ HF-KN, HF-KP(ที่มีเกียร์ทด)

Application Examples

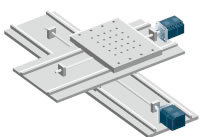

■ X-Y tables

For X-Y positioning system for machine tools, inspection

machines, etc.

● The high-performance servo system enables high-speed

positioning.

● 17-bit encoder enables high-accuracy positioning.

● Shorter tact time is achieved by suppressing vibrations.

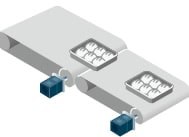

■ Conveyors

For conveyance between processes of each work, etc.

● High acceleration/deceleration and high-speed

conveyance are enabled by the servo system.

● Constant-speed feed is available with a highly stable

speed.

● Optimal gain can be set by the auto tuning function when using various works.

■ Food processing machines

For food processing, positioning of liquid filling nozzle,

unwinding of wrapping material, etc.

● The high-performance servo system enables shorter

tact time.

● The tough drive function improves machine operating

rate.

● HF-KN series is rated IP65 as standard (excluding the shaft-through portion).

■ Loaders/unloaders, feeders and sliders

Work positioning and conveyance for automated warehouse,

press machines, etc.

● The high speed and accurate positioning improves

productivity.

● Compact machine can be achieved by the small-size servo amplifier and servo motor.

■ Textile machines

For string unwinding, traversing, etc.

● Compact machine can be achieved by the small-size

servo amplifier and servo motor.

● High acceleration/deceleration and high-speed

conveyance are enabled by the servo system.

● HF-KN series is rated IP65 as standard (excluding the shaft-through portion).

■ Robots

For picking up and transferring processing work

● Shorter tact time is achieved by suppressing

vibrations.

● Optimal gain can be set by the auto tuning function

when using various works.

● Compact machine can be achieved by the small-size servo amplifier and servo motor.

■ Semiconductor/liquid crystal/solar battery producing equipment

For peripheral axes of board, panel conveyance, etc.

● Easy maintenance with the separated power supply for

main and control circuits.

● The tough drive function improves machine operating

rate.

● Compact machine can be achieved by the small-size servo amplifier and servo motor.

■ Replacement of stepping motors, DC motors, air actuator or inverters

By introducing the servo system, the driving section of the

legacy products can be faster and more accurate.

● Replacement of the air actuator enables more accurate

driving section.

● Step-out occurred with the stepping motor is no

longer an issue.

● Replacement of the inverter improves speed and accuracy.