Product

Product Features

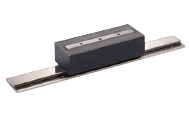

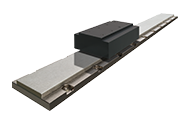

MELSERVO-JET Series Linear Servo Motors

Basic Performance

- Maximum speed: 3 m/s (LM-H3 series), 6.5 m/s (LM-AJ series)

- Maximum thrust range: 175 N to 1800 N. Small size and high thrust.

- The linear servo motors are compatible with a variety of serial interface linear encoders. The linear encoder resolution ranges from 1 nm and up.

- High-performance systems such as high-accuracy tandem synchronous control are achieved with CC-Link IE TSN.

- The linear servo motors feature environmental resistance, designed for an altitude of 2000 m and an ambient temperature of up to 60 ℃. *1, 2

- *1. Derate the speed/thrust when using the linear servo motors at an altitude exceeding 1000 m and at high ambient temperatures.

- *2. LM-AJ series is designed for an altitude of 1000 m and an ambient temperature of up to 40 ℃.

Higher Machine Performance

For higher machine performance

- Improved productivity due to high-speed driving part.

For easier use

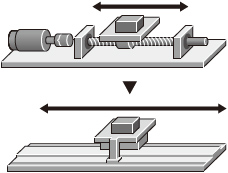

- The linear servo motors enable a simple and compact machine with high rigidity.

- Smooth operation and clean systems are achieved.

For flexible machine configurations

- Multi-head and tandem systems are easily configured.

- The linear servo motors are suitable for long-stroke applications.

[Offers more advantage than conventional ball screw driving systems]