Product Features

High-speed Synchronous Network SSCNETIII/H

Deterministic and Synchronized Communication

Complete deterministic and synchronized communication is achieved with SSCNETIII/H, offering technical advantages in machines such as printing and food processing machines that require synchronous accuracy.

Central Control with Network

Large amounts of servo data are exchanged in real-time between the controller and the servo amplifier. Using MELSOFT MR Configurator2 on a personal computer that is connected to the Simple Motion module QD77MS helps consolidate information such as parameter settings and monitoring for the multiple servo amplifiers.

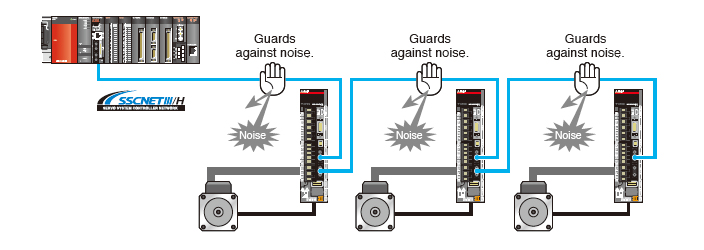

No Transmission Collision

The fiber-optic cables thoroughly shut out noise that enters from the power cable or external devices.

Noise tolerance is dramatically improved as compared to metal cables.

Positioning Control

Execute positioning control with the data table method.

- The Data Setting Assistant function simplifies settings.

- Positioning data can be set very simply by using functions such as Automatic Command Speed Calculation, Offline Simulation, and automatic calculation of auxiliary arc, etc.

Synchronous Control

Synchronous control can be easily achieved with software by placing mechanical modules on screen, such as the gear, shaft, speed change gear and cam.

- The Synchronous control is easily performed with parameter settings. There is no need to create complicated programs.

- Synchronous control is started/stopped on axis-by-axis basis. The synchronous control axis and positioning control axis can exist together in a program.

- The movement amount of main shaft is transmitted to the output axis via the clutch.

Cam Control

Various cam pattern can be easily created.

- Cam control has become more flexible. Various cam patterns are available.

- You can set the stroke, speed, acceleration and throb while simultaneously checking the profile on a graph.

- The created cam data are easily viewed as thumbnails.

- Cam data is imported and exported in CSV format.

Control Flow

The start of positioning operation by the Simple Motion module is programmed in PLC CPU.

The Simple Motion module starts operation from the designated positioning data No. and continues operation until the operation pattern ends.

High Compatibility with the Previous Models

The Positioning module (QD75MH) projects and sequence programs are easily diverted to the Simple Motion module (QD77MS/LD77MS).

The replacement to QD77MS/LD77MS is easily completed without replacing the prior model of servo amplifier MR-J3-B.

Functions List

| Simple Motion Module | |||

|---|---|---|---|

| QD77MS16 | QD77MS4 | QD77MS2 | |

| Servo amplifier connection method | SSCNETIII/H (150Mbps) | ||

| Maximum distance between stations [m(ft.)] | 100 (328.08) | ||

| Connectable servo amplifier | MR-J4(W)-B | ||

| Number of control axes | 16 axes | 4 axes | 2 axes |

| Operation cycle | 0.88/1.77 | From 0.88 | |

| Engineering environment | Simple Motion Module Setting Tool (Note-1) MR Configurator2 | ||

| Control modes | PTP (Point To Point) control, Position control, Speed control, Torque control, Tightening & press-fit control, Cam control, Advanced synchronous control, 2 axes/3 axes/4 axes Linear interpolation, 2 axes Circular interpolation, Trajectory control, Speed/position switching control (ABS/INC), Position/speed switching control (INC) | ||

| Control unit | mm, inch, degree, PLS | ||

| Positioning data | 600 data (positioning data No. 1 to 600)/axis (Can be set with MELSOFT GX Works2 or Sequence program.) | ||

| Acceleration/deceleration method | Trapezoidal acceleration/deceleration, S-curve acceleration/deceleration | ||

| Manual control | JOG operation, Manual pulse generator operation, Inching operation | ||

| Functions that change control details | Current value change, Target position change function, Torque change function, Speed change function, Override function, Acceleration/deceleration time change function | ||

| Home position return method | Near-point dog method, Count method 1, Count method 2, Data set method, Scale home position signal detection method | ||

| Auxiliary function | Forced stop function, Hardware stroke limit function, Software stroke limit function, Absolute position system, Amplifier-less operation function, Unlimited length feed, Optional data monitor function, Mark detection function, Flash ROM backup, Module error collection function, M-code output function, Digital oscilloscope function, Cam auto-generation function | ||

| Number of I/O occupying points | 32 points (I/O allocation: Intelligent function module, 32 points) | ||

| 5VDC internal current consumption [A] | 0.75 | 0.6 | 0.6 |

| Mass [kg] | 0.16 | 0.16 | 0.15 |

(Note-1): Simple Motion Module Setting Tool is included in MELSOFT GX Works2.